mobile lifting gantry

The Advantages and Applications of Mobile Lifting Gantry Systems

Mobile lifting gantries represent a significant innovation in the realm of material handling and lifting solutions. These versatile structures are designed to facilitate the lifting and transportation of various loads in a wide array of environments, from industrial settings to construction sites. With their capability to be easily moved, adjusted, and assembled, mobile lifting gantries offer a flexible solution for many businesses.

One of the primary advantages of mobile lifting gantries is their portability. Unlike traditional cranes, which are often fixed in position, a mobile gantry can be relocated to different sites with minimal effort. This portability is crucial for businesses that operate in dynamic environments, where the need for lifting equipment can change rapidly. For instance, in construction projects that span several locations or in maintenance tasks across large facilities, a mobile lifting gantry can be quickly moved to meet the specific lifting requirements at any given moment.

In addition to their mobility, these gantries are typically adjustable in height and span. This feature allows operators to customize the gantry to suit the specific dimensions of the load being lifted. Whether it’s lifting heavy machinery, large components, or even smaller items within a warehouse, the ability to adjust the gantry ensures optimal safety and efficiency during the lifting process. Furthermore, most mobile lifting gantries are equipped with wheels, making them easy to maneuver, even in tight spaces.

Safety is a paramount concern when it comes to lifting operations, and mobile lifting gantries are designed with safety features that help to minimize risks. Many models come with locking mechanisms to stabilize the structure when in use, preventing any unwanted movement during operations. Additionally, users can choose gantries that are constructed from sturdy materials, designed to handle substantial loads while adhering to industry safety standards. This ensures that both operators and bystanders are protected during lifting tasks.

mobile lifting gantry

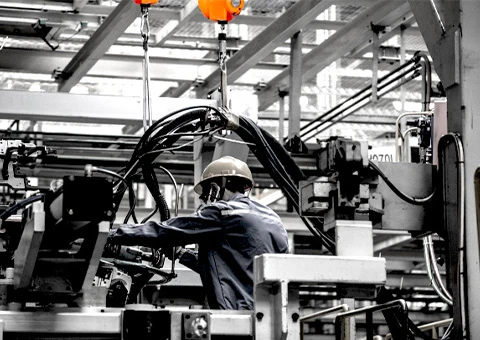

The flexibility of mobile lifting gantries spans various industries and applications. In manufacturing, they play a crucial role in assembly lines where heavy components need to be lifted and positioned accurately. In warehouses, these gantries can be used to transport goods across aisles or to assist in loading and unloading products from trucks. The automotive industry frequently utilizes mobile lifting gantries for tasks like engine removal and component repairs, making it a versatile tool for maintenance operations.

Moreover, educational institutions and laboratories can benefit from mobile lifting gantries. They provide essential support for lifting equipment, allowing researchers and students to handle heavy items safely. Whether it’s mounting instruments for experiments or transporting apparatus, mobile gantries can enhance productivity and safety within these environments.

Technological advancements have also led to the evolution of mobile lifting gantries. Modern designs may include electric hoists, remote control capabilities, and integrated safety features such as overload protection systems. These innovations further improve usability and safety, making it easier for operators to manage lifting tasks without risking injury or damage to equipment.

In conclusion, mobile lifting gantries are essential tools for a variety of sectors, offering unparalleled mobility, adjustability, and safety features. Their ability to be easily relocated and configured to meet the needs of different tasks makes them an invaluable asset in any workplace involving lifting operations. As industries continue to evolve and demand greater flexibility and efficiency, the use of mobile lifting gantries is expected to grow, providing effective solutions for lifting challenges across the globe. Whether in construction, manufacturing, or research, investing in a mobile lifting gantry can significantly enhance operational efficiency and workplace safety.

-

The Power of Trolley Cargo and Machinery Moving SolutionsNewsAug.22,2025

-

Exploring Magnetic Lifting Devices for Efficient Steel Plate HandlingNewsAug.22,2025

-

The Essential Guide to Portal CraneNewsAug.22,2025

-

Enhancing Efficiency in Permanent Magnetic LiftersNewsAug.22,2025

-

Heavy-Duty Machinery Movers and Material Handling SolutionsNewsAug.22,2025

-

The Comprehensive Guide to Adjustable Gantry CranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025