types of gantry cranes

Types of Gantry Cranes An Overview

Gantry cranes are vital equipment in the construction and manufacturing industries, known for their ability to lift and move heavy materials with ease and efficiency. Unlike overhead cranes, gantry cranes are freestanding structures that can traverse the work area, making them versatile tools for various applications. This article aims to provide an overview of the different types of gantry cranes, highlighting their unique features, uses, and advantages.

1. Full Gantry Cranes

Full gantry cranes are characterized by their complete structural framework consisting of two legs that support a horizontal beam, allowing for significant lift heights and spans. This type is commonly used in outdoor environments, such as shipping yards, construction sites, and industrial facilities. Full gantry cranes have both a travelling mechanism and a lifting mechanism, which allows them to move along tracks at the ground level, offering excellent mobility and flexibility in operations.

Advantages - High lifting capacities, ideal for heavy loads. - Versatile in various applications, including material handling and construction. - Capable of operating in large open spaces.

2. Semi-Gantry Cranes

Unlike full gantry cranes, semi-gantry cranes have only one leg supported by the ground while the other side is supported by an existing structure, such as an overhead beam. This design is advantageous in indoor settings or areas where space is limited. Semi-gantry cranes can be an economical solution since they utilize existing infrastructure, reducing the need for additional construction.

Advantages - Space-saving design suitable for tight environments. - Cost-effective due to reduced construction needs. - Ideal for applications where overhead conditions permit.

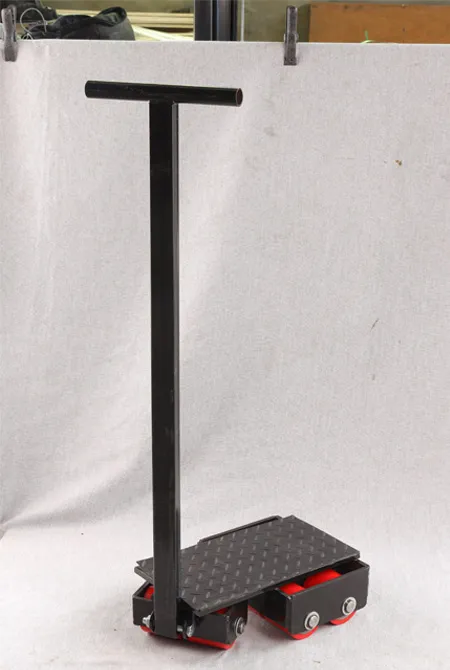

Portable gantry cranes are lightweight and easy to assemble, designed for maneuverability and flexibility. These cranes typically feature adjustable height options and can be moved wherever needed, making them a popular choice for smaller jobs and workshops. They are commonly used for lifting and positioning loads in locations that do not require permanent equipment installation.

types of gantry cranes

Advantages - Lightweight and easy to transport. - Adjustable height for versatility in different tasks. - Suitable for a range of applications from small engine repairs to light construction.

4. Electric Gantry Cranes

Electric gantry cranes utilize electric hoists to lift and lower loads, providing smoother and more efficient operations compared to manual lifting systems. These cranes are commonly employed in manufacturing and assembly lines, where efficiency and precision are paramount. Electric gantry cranes can be configured as either full or semi-gantry designs, depending on the application requirements.

Advantages - Increased lifting efficiency with electric power. - Reduced physical strain on workers during operations. - Enhanced safety features such as overload protection and smoother movements.

5. Container Gantry Cranes (RTG and RMG)

Container gantry cranes, including Rubber-Tyred Gantry (RTG) cranes and Rail-Mounted Gantry (RMG) cranes, are specifically designed for container handling in ports and freight terminals. RTG cranes run on rubber tires, allowing them to maneuver flexibly within container yards. In contrast, RMG cranes run on fixed tracks and are designed for high-density stacking and automated operations.

Advantages - Optimized for high-volume container handling. - Improved efficiency in loading and unloading shipping containers. - Capable of stacking containers for better space utilization at ports.

Conclusion

Gantry cranes play a significant role in various industries, enabling efficient material handling and enhancing productivity. The choice of crane depends on the specific needs of the job, including factors such as load capacity, workspace, and operational needs. Whether it’s a full gantry crane for heavy lifting in construction or a portable gantry crane for smaller workshops, understanding the different types of gantry cranes helps businesses select the right equipment for their operations. As industrial needs continue to evolve, advancements in gantry crane technology will likely enhance their functionality and efficiency, further solidifying their importance in modern industry.

-

4000 lb Gantry Crane: Heavy-Duty, Adjustable Lifting SolutionsNewsAug.28,2025

-

The Power of Trolley Cargo and Machinery Moving SolutionsNewsAug.22,2025

-

Exploring Magnetic Lifting Devices for Efficient Steel Plate HandlingNewsAug.22,2025

-

The Essential Guide to Portal CraneNewsAug.22,2025

-

Enhancing Efficiency in Permanent Magnetic LiftersNewsAug.22,2025

-

Heavy-Duty Machinery Movers and Material Handling SolutionsNewsAug.22,2025

-

The Comprehensive Guide to Adjustable Gantry CranesNewsAug.22,2025