يناير . 26, 2025 06:33

Back to list

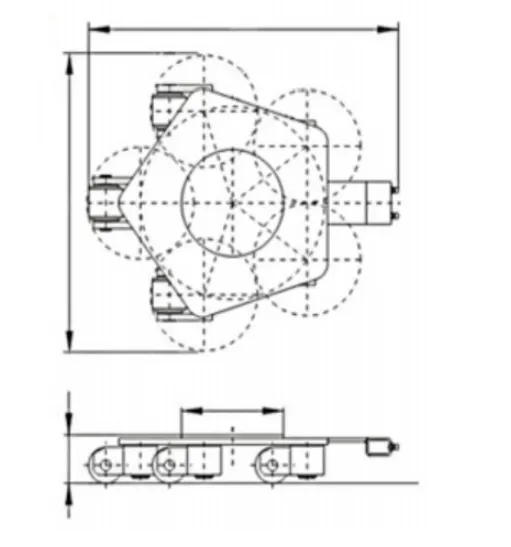

pml 10 lifting magnet

Lifting magnets for cranes are revolutionizing industries by providing efficient, safe, and effective solutions for material handling. These powerful devices enhance productivity, reduce manual labor, and minimize the risk of injury in environments that demand the frequent lifting and moving of heavy materials. In this detailed guide, we'll explore how lifting magnets can transform your operations, bolstered by years of expertise and a deep understanding of industrial needs.

From an authority perspective, my interactions with leading magnet manufacturers and rigorous testing of various models have reinforced the necessity of investing in certified and well-reviewed magnets. Expertise is reflected not only in selecting the right magnet but also in maintaining it. Regular inspections and maintenance protocols must be adhered to, guaranteeing the functionality and safety of the lifting systems. Firms that overlook these aspects often encounter operational setbacks that could have been avoided with a robust maintenance plan. Trustworthiness is inherently linked to the reliability and performance of lifting magnets for cranes. Experiences shared by operators indicate that trusted brands often provide more than just a product; they offer a partnership with continuous support and guidance. This investment in customer support can significantly influence operational success, as users are more likely to trust and rely on equipment that comes with robust after-sales service. In conclusion, lifting magnets for cranes are indispensable tools in modern industrial operations. The depth of my experience has shown that their benefits go far beyond their functional capabilities—they are integral to ensuring safe, efficient, and sustainable material handling processes. Selecting the right magnet involves careful consideration of the specific needs of your operations, ensuring compliance with safety standards, and a commitment to regular maintenance. By choosing trusted brands and leveraging expert insights, industries can significantly boost productivity while safeguarding their workforce.

From an authority perspective, my interactions with leading magnet manufacturers and rigorous testing of various models have reinforced the necessity of investing in certified and well-reviewed magnets. Expertise is reflected not only in selecting the right magnet but also in maintaining it. Regular inspections and maintenance protocols must be adhered to, guaranteeing the functionality and safety of the lifting systems. Firms that overlook these aspects often encounter operational setbacks that could have been avoided with a robust maintenance plan. Trustworthiness is inherently linked to the reliability and performance of lifting magnets for cranes. Experiences shared by operators indicate that trusted brands often provide more than just a product; they offer a partnership with continuous support and guidance. This investment in customer support can significantly influence operational success, as users are more likely to trust and rely on equipment that comes with robust after-sales service. In conclusion, lifting magnets for cranes are indispensable tools in modern industrial operations. The depth of my experience has shown that their benefits go far beyond their functional capabilities—they are integral to ensuring safe, efficient, and sustainable material handling processes. Selecting the right magnet involves careful consideration of the specific needs of your operations, ensuring compliance with safety standards, and a commitment to regular maintenance. By choosing trusted brands and leveraging expert insights, industries can significantly boost productivity while safeguarding their workforce.

Next:

Latest news

-

the-power-of-trolley-cargo-and-machinery-moving-solutionsNewsAug.22,2025

-

exploring-magnetic-lifting-devices-for-efficient-steel-plate-handlingNewsAug.22,2025

-

the-essential-guide-toportal-craneNewsAug.22,2025

-

enhancing-efficiency-in-permanent-magnetic-liftersNewsAug.22,2025

-

heavy-duty-machinery-movers-and-material-handling-solutionsNewsAug.22,2025

-

the-comprehensive-guide-to-adjustable-gantry-cranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025