يناير . 24, 2025 02:31

Back to list

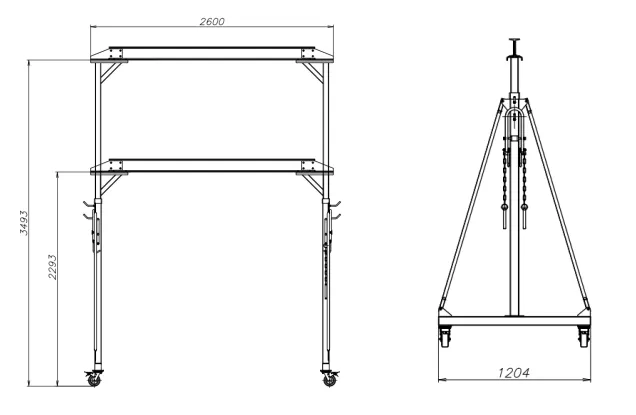

heavy machinery moving equipment

Machinery rollers are crucial components in the realm of industrial operations, facilitating the smooth movement and transportation of heavy machinery and considerable loads. Their importance may not be immediately apparent, yet their influence on operational efficiency and workplace safety is profound. Diving into the specifics of machinery rollers reveals insights into their construction, applications, and the critical role they play in various industries, thereby showcasing their unmatched contribution to mechanical handling.

One notable real-world experience comes from a global logistics company that optimized its warehouse operations by switching to a high-grade polymer fascia for their conveyor rollers. This transition not only reduced the noise levels significantly, improving the overall working environment, but it also resulted in a 15% reduction in energy consumption, attributed to the decreased friction. Such experiences highlight the tangible benefits that machinery rollers bring, emphasizing their role in enhancing operational efficiency and sustainability. Moreover, recent innovations in machinery roller technology, such as the development of smart rollers equipped with sensors, have introduced a new dimension to their functionality. These advanced rollers can monitor parameters like load weight and bearing temperature in real-time, providing data that enables predictive maintenance—a strategic shift that minimizes unexpected maintenance costs and operational interruptions. Selecting and maintaining appropriate machinery rollers is a nuanced task that demands both industry knowledge and practical experience. For businesses, investing in high-quality rollers translates to optimized operations and safety—a balance that contributes to long-term success. The machinery roller market continues evolving, with manufacturers striving to enhance performance through innovative materials and smart technology, showing a commitment to addressing the diverse needs of modern industries. In summation, machinery rollers play an indispensable role in various industrial settings. Their reliability, when paired with technical expertise and authority in selection and maintenance, ensures that they remain a pivotal component in advancing efficiency and safety in operation. As industries evolve, the advancements in machinery roller technology hold the promise of further enhancing their contribution to mechanical handling and transport solutions for businesses worldwide.

One notable real-world experience comes from a global logistics company that optimized its warehouse operations by switching to a high-grade polymer fascia for their conveyor rollers. This transition not only reduced the noise levels significantly, improving the overall working environment, but it also resulted in a 15% reduction in energy consumption, attributed to the decreased friction. Such experiences highlight the tangible benefits that machinery rollers bring, emphasizing their role in enhancing operational efficiency and sustainability. Moreover, recent innovations in machinery roller technology, such as the development of smart rollers equipped with sensors, have introduced a new dimension to their functionality. These advanced rollers can monitor parameters like load weight and bearing temperature in real-time, providing data that enables predictive maintenance—a strategic shift that minimizes unexpected maintenance costs and operational interruptions. Selecting and maintaining appropriate machinery rollers is a nuanced task that demands both industry knowledge and practical experience. For businesses, investing in high-quality rollers translates to optimized operations and safety—a balance that contributes to long-term success. The machinery roller market continues evolving, with manufacturers striving to enhance performance through innovative materials and smart technology, showing a commitment to addressing the diverse needs of modern industries. In summation, machinery rollers play an indispensable role in various industrial settings. Their reliability, when paired with technical expertise and authority in selection and maintenance, ensures that they remain a pivotal component in advancing efficiency and safety in operation. As industries evolve, the advancements in machinery roller technology hold the promise of further enhancing their contribution to mechanical handling and transport solutions for businesses worldwide.

Next:

Latest news

-

the-power-of-trolley-cargo-and-machinery-moving-solutionsNewsAug.22,2025

-

exploring-magnetic-lifting-devices-for-efficient-steel-plate-handlingNewsAug.22,2025

-

the-essential-guide-toportal-craneNewsAug.22,2025

-

enhancing-efficiency-in-permanent-magnetic-liftersNewsAug.22,2025

-

heavy-duty-machinery-movers-and-material-handling-solutionsNewsAug.22,2025

-

the-comprehensive-guide-to-adjustable-gantry-cranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025