Efficient Handheld Lifting Magnets for Safe Material Handling Solutions

Hand Lifting Magnets Empowering Material Handling with Ease and Safety

In today's industrial and warehousing environments, efficiency and safety are paramount. One of the innovative tools that have gained significant attention in this realm is the hand lifting magnet. These devices are designed to facilitate the movement of heavy metallic objects with minimal effort, thereby enhancing productivity and reducing the risk of workplace injuries.

What are Hand Lifting Magnets?

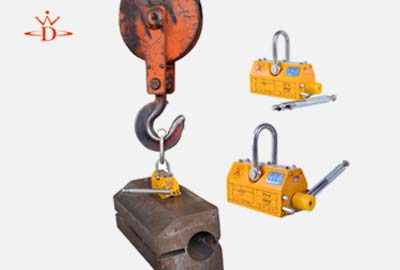

Hand lifting magnets, also known as magnetic lifters, are tools that utilize the principle of magnetism to lift and maneuver ferrous (iron or steel) objects. Typically made from strong permanent magnets, these devices allow users to pick up heavy loads without the need for additional equipment such as cranes or forklifts. Hand lifting magnets come in various sizes and lifting capacities, making them suitable for different applications, from small workshops to large manufacturing plants.

How Do They Work?

The functioning of hand lifting magnets is relatively straightforward. Most models include a simple on-off switch that activates or deactivates the magnetic force. When engaged, the magnet adheres to the metal surface, allowing users to lift the object by gripping the attached handle. The design not only ensures a solid grip on the surface but also provides stability and safety during the lifting process.

The strength of these magnets is measured in terms of their lifting capacity, often ranging from a few hundred pounds to several tons, depending on the model. High-quality magnetic lifters can support heavier loads with ease while maintaining a compact design, which is highly advantageous in tight working spaces.

Advantages of Hand Lifting Magnets

1. Ease of Use One of the primary benefits of hand lifting magnets is their simplicity. Workers can quickly learn to use these devices, which reduces the training time associated with handling more complex lifting equipment.

2. Increased Safety Traditional lifting methods often involve manual handling or the use of more cumbersome equipment, which can lead to injuries. Hand lifting magnets eliminate the need for heavy lifting, thereby decreasing the risk of strains and other musculoskeletal injuries.

hand lifting magnets

3. Time Efficiency With the ability to lift and move items quickly and easily, hand lifting magnets enhance the overall efficiency of material handling processes. Workers spend less time setting up heavy machinery and more time on productive tasks.

4. Versatility These magnets can be used across various industries, including manufacturing, construction, shipping, and scrap processing. They are effective for lifting steel plates, pipes, and various other components used in industrial applications.

5. Cost-Effective Solution Investing in hand lifting magnets can be more economical in the long run. They reduce the need for heavy machinery, maintenance costs, and labor associated with manual lifting.

Applications in Various Industries

Hand lifting magnets find their place in numerous sectors. In manufacturing, they are used not only for lifting raw materials but also for assembling components on production lines. In shipping and logistics, these magnets streamline the loading and unloading processes, allowing for quicker turnaround times. In the construction industry, they assist in placing beams and panels securely without requiring cranes.

Considerations When Choosing Hand Lifting Magnets

When selecting the appropriate hand lifting magnet for a specific application, several factors should be considered. First and foremost is the lifting capacity; it's crucial to choose a magnet that can handle the job's weight requirements. Additionally, the type of material being lifted, the thickness of the object, and the surface conditions (e.g., rough or smooth) can all impact the effectiveness of the magnet.

Furthermore, it's essential to look for quality and safety certifications from reputable manufacturers to ensure reliability during operation. Proper maintenance and regular inspections are also vital to prolonging the lifespan of the equipment and ensuring user safety.

Conclusion

Hand lifting magnets represent a significant advancement in material handling technology. Their ability to enhance efficiency, safety, and versatility makes them an invaluable tool in various industrial applications. As businesses continue to seek ways to improve their operations, investing in hand lifting magnets could be a decisive step towards achieving greater productivity and a safer workplace.

-

The Power of Trolley Cargo and Machinery Moving SolutionsNewsAug.22,2025

-

Exploring Magnetic Lifting Devices for Efficient Steel Plate HandlingNewsAug.22,2025

-

The Essential Guide to Portal CraneNewsAug.22,2025

-

Enhancing Efficiency in Permanent Magnetic LiftersNewsAug.22,2025

-

Heavy-Duty Machinery Movers and Material Handling SolutionsNewsAug.22,2025

-

The Comprehensive Guide to Adjustable Gantry CranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025