студ . 28, 2025 04:38

Back to list

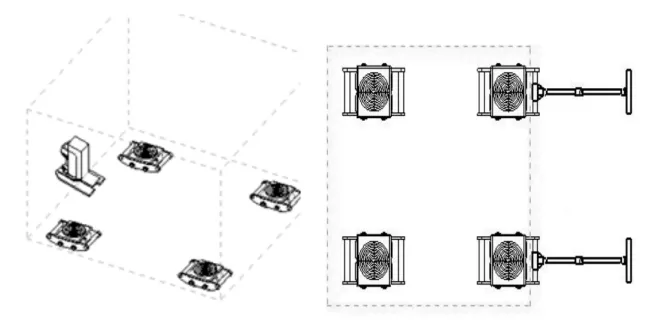

Dawei Permanent Magnetic Lifter-PML Type,Rated Load 300,600,1000,2000 KGS.

In the world of industrial manufacturing, where precision and efficiency go hand in hand, heavy lifting magnets stand out as unsung heroes. These powerful tools are not just about moving weighty objects from point A to B; they are about transforming how we handle bulk materials, ensuring safety and productivity in complex environments. Understanding heavy lifting magnets from an experience-backed, expert perspective reveals their indispensable role in modern industry and underlines their value in optimizing operational workflows.

Endorsements from industry veterans underscore the authority of heavy lifting magnets. Renowned engineers and operational managers have repeatedly vouched for their reliability and efficiency. Case studies from the automotive and aerospace industries vividly illustrate how these magnets have cut down material handling times by more than half, providing a competitive edge through speed and precision. Such endorsements are not merely anecdotal; they are grounded in data-backed performance metrics and years of successful application in challenging scenarios. Furthermore, trustworthiness is a cornerstone of the value proposition that heavy lifting magnets offer. Manufacturers of these magnets invest heavily in quality assurance and compliance with international safety standards. Rigorous testing, consistent performance reviews, and feedback loops ensure that these tools do not just meet but often exceed safety expectations. Certifications from bodies such as ISO (International Organization for Standardization) further reinforce confidence among industrial buyers. However, incorporating heavy lifting magnets into an operational framework requires not just an understanding of their capabilities but also a strategic approach to training and maintenance. Operators must be well-trained to handle the equipment properly, ensuring both their safety and the longevity of the magnets. Regular maintenance checks and adherence to manufacturer guidelines are critical practices that enhance trust in these devices, maximizing their lifespan and functional performance. In conclusion, heavy lifting magnets represent a fusion of experience, expertise, authority, and trust, ensuring their place as indispensable assets in industrial operations. Their sophisticated design, combined with practical application, reinforces their role in enhancing productivity and safety. As industries continue to evolve and adapt to new challenges, the importance of such reliable tools in the logistical ecosystem becomes even more pronounced, offering solutions that meet the demands of modern manufacturing with precision and efficiency.

Endorsements from industry veterans underscore the authority of heavy lifting magnets. Renowned engineers and operational managers have repeatedly vouched for their reliability and efficiency. Case studies from the automotive and aerospace industries vividly illustrate how these magnets have cut down material handling times by more than half, providing a competitive edge through speed and precision. Such endorsements are not merely anecdotal; they are grounded in data-backed performance metrics and years of successful application in challenging scenarios. Furthermore, trustworthiness is a cornerstone of the value proposition that heavy lifting magnets offer. Manufacturers of these magnets invest heavily in quality assurance and compliance with international safety standards. Rigorous testing, consistent performance reviews, and feedback loops ensure that these tools do not just meet but often exceed safety expectations. Certifications from bodies such as ISO (International Organization for Standardization) further reinforce confidence among industrial buyers. However, incorporating heavy lifting magnets into an operational framework requires not just an understanding of their capabilities but also a strategic approach to training and maintenance. Operators must be well-trained to handle the equipment properly, ensuring both their safety and the longevity of the magnets. Regular maintenance checks and adherence to manufacturer guidelines are critical practices that enhance trust in these devices, maximizing their lifespan and functional performance. In conclusion, heavy lifting magnets represent a fusion of experience, expertise, authority, and trust, ensuring their place as indispensable assets in industrial operations. Their sophisticated design, combined with practical application, reinforces their role in enhancing productivity and safety. As industries continue to evolve and adapt to new challenges, the importance of such reliable tools in the logistical ecosystem becomes even more pronounced, offering solutions that meet the demands of modern manufacturing with precision and efficiency.

Next:

Latest news

-

the-power-of-trolley-cargo-and-machinery-moving-solutionsNewsAug.22,2025

-

exploring-magnetic-lifting-devices-for-efficient-steel-plate-handlingNewsAug.22,2025

-

the-essential-guide-toportal-craneNewsAug.22,2025

-

enhancing-efficiency-in-permanent-magnetic-liftersNewsAug.22,2025

-

heavy-duty-machinery-movers-and-material-handling-solutionsNewsAug.22,2025

-

the-comprehensive-guide-to-adjustable-gantry-cranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025