Mar . 04, 2025 03:25

Back to list

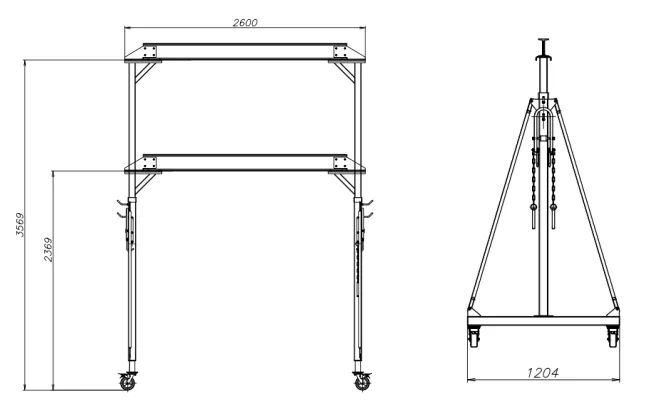

heavy machine dollies

When it comes to the logistics of moving heavy machinery, the right tools are paramount for efficiency and safety. Heavy machine dollies, known for their robustness and versatility, have emerged as indispensable aids in various industrial sectors. As an expert in this domain, I have witnessed firsthand the profound impact these devices have on operational workflows. In this article, we delve into the multifaceted applications, benefits, and considerations surrounding heavy machine dollies, offering insights gained through years of industry experience.

Trustworthiness in this domain stems from a combination of product quality and adherence to safety standards. Reputable manufacturers of heavy machine dollies subject their products to rigorous testing, ensuring compliance with industry norms. It is advisable for buyers to seek dollies that boast certifications from recognized bodies, providing assurance of their credibility and performance reliability. Furthermore, sourcing equipment from established brands often comes with the bonus of professional support and after-sales service, fostering long-term customer trust. Expertise in the use of heavy machine dollies involves not only selecting the right model but also understanding maintenance practices. Regular inspections are essential to identify wear and tear, particularly in wheels and connecting joints. Lubricating moving parts and replacing compromised components can significantly extend the lifespan of these dollies, reinforcing their value as a long-term investment. From an experiential standpoint, integrating heavy machine dollies into logistical operations has proven transformative for numerous businesses. Their ability to safely transport massive loads with minimal human effort reduces the likelihood of injuries, thus promoting a safer working environment. This, in turn, represents a boost in morale, as employees operate within a framework that prioritizes their well-being. In conclusion, the strategic deployment of heavy machine dollies can revolutionize the approach to heavy equipment relocation across industries. By providing tailored solutions that combine strength, agility, and reliability, these tools stand as vital assets for operational success. For businesses seeking to enhance their logistical capabilities, investing in high-quality heavy machine dollies backed by expert guidance is a forward-thinking decision. This not only ensures seamless operations but also aligns with best practices in safety and efficiency, hallmarks of industry leadership.

Trustworthiness in this domain stems from a combination of product quality and adherence to safety standards. Reputable manufacturers of heavy machine dollies subject their products to rigorous testing, ensuring compliance with industry norms. It is advisable for buyers to seek dollies that boast certifications from recognized bodies, providing assurance of their credibility and performance reliability. Furthermore, sourcing equipment from established brands often comes with the bonus of professional support and after-sales service, fostering long-term customer trust. Expertise in the use of heavy machine dollies involves not only selecting the right model but also understanding maintenance practices. Regular inspections are essential to identify wear and tear, particularly in wheels and connecting joints. Lubricating moving parts and replacing compromised components can significantly extend the lifespan of these dollies, reinforcing their value as a long-term investment. From an experiential standpoint, integrating heavy machine dollies into logistical operations has proven transformative for numerous businesses. Their ability to safely transport massive loads with minimal human effort reduces the likelihood of injuries, thus promoting a safer working environment. This, in turn, represents a boost in morale, as employees operate within a framework that prioritizes their well-being. In conclusion, the strategic deployment of heavy machine dollies can revolutionize the approach to heavy equipment relocation across industries. By providing tailored solutions that combine strength, agility, and reliability, these tools stand as vital assets for operational success. For businesses seeking to enhance their logistical capabilities, investing in high-quality heavy machine dollies backed by expert guidance is a forward-thinking decision. This not only ensures seamless operations but also aligns with best practices in safety and efficiency, hallmarks of industry leadership.

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025