Lifting Solutions Using Industrial Magnets for Heavy Load Handling and Transportation

The Role of Industrial Magnets in Lifting Applications

In the modern industrial landscape, the demand for efficient and reliable lifting solutions has never been higher. One of the most innovative and effective technologies that has emerged in recent years is the use of industrial magnets for lifting applications. These powerful devices offer a blend of safety, efficiency, and versatility, making them indispensable in various sectors, including manufacturing, construction, and logistics.

Understanding Industrial Magnets

Industrial magnets come in various forms, each designed for specific applications. The most common types used for lifting are permanent magnets and electromagnets. Permanent magnets maintain their magnetic field without the need for an external power source, while electromagnets generate a magnetic field when an electric current passes through them. Each type has its advantages permanent magnets are often more compact and straightforward, whereas electromagnets can provide adjustable lifting capabilities based on the current applied.

Safety and Reliability

One of the primary reasons industrial magnets are favored for lifting operations is their inherent safety features. Unlike mechanical devices, which can fail due to wear and tear, industrial magnets offer a robust and durable solution. They provide a firm grip on ferromagnetic materials, reducing the risk of load drops and accidents. Additionally, many industrial lifting magnets are designed with safety factors that ensure they can support significantly more than their rated capacity, adding another layer of reliability.

Furthermore, industrial magnets are often used in conjunction with safety systems such as fallback devices and alarms to alert operators if the lifting force is compromised. The combination of these features makes industrial magnets a preferred choice in high-stakes environments where safety is paramount.

Versatility in Applications

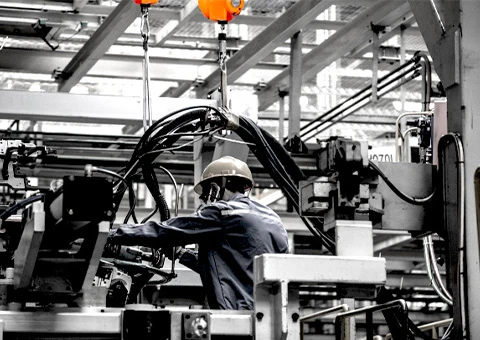

The versatility of industrial magnets extends across various industries and lifting scenarios. In manufacturing, for example, these magnets are utilized for lifting heavy steel plates, coils, and other materials with precision and ease. This efficiency not only speeds up production times but also reduces the risk of workplace injuries associated with manual lifting.

industrial magnets for lifting

In the construction sector, industrial magnets play a critical role in handling reinforced steel bars and other heavy items

. They enable quick and secure transport from one area to another without the need for complex rigging systems, thus streamlining operations and enhancing productivity.Moreover, the logistics industry benefits significantly from industrial lifting magnets. They are employed in warehouses and distribution centers for loading and unloading heavy goods from trucks and containers. This not only accelerates the handling process but also minimizes the risk of damage to goods often associated with traditional lifting methods.

Environmental Considerations

Another noteworthy benefit of using industrial magnets for lifting is their impact on energy efficiency and environment-friendly operations. Permanent magnets, for instance, do not require any electrical energy to maintain their magnetic field, making them an energy-efficient solution. Even in the case of electromagnets, modern designs are optimized to consume minimal power while providing high lifting capacities. This reduction in energy consumption aligns with the increasing emphasis on sustainable practices in industrial operations.

Future Trends

As technology continues to evolve, the future of industrial magnets in lifting applications looks promising. Research is ongoing to improve the materials and designs of magnetic systems, enhancing their lifting capabilities, durability, and efficiency. Innovations such as automated control systems will further enhance the usability of magnetic lifters, allowing for precise and automated operations in dynamic environments.

In addition to traditional materials like steel, new advancements might lead to the use of magnets in handling alternative materials, thus broadening their application scope. Industries that rely heavily on diverse materials will find industrial magnets increasingly useful in meeting their lifting requirements.

Conclusion

In conclusion, industrial magnets for lifting applications represent a cutting-edge solution to modern industrial challenges. Their safety, reliability, and versatility make them a valuable asset across various sectors. As technology progresses and new innovations emerge, the role of industrial magnets in lifting operations is set to expand, ensuring they remain at the forefront of efficient and safe material handling in the industrial world. With their numerous advantages, it's clear that industrial magnets will play a significant role in shaping the future of lifting technologies.

-

Affordable 2000 lb Gantry Crane | Heavy-Duty & PortableNewsSep.01,2025

-

4000 lb Gantry Crane | Adjustable, Heavy-Duty Lifting SolutionsNewsAug.31,2025

-

Portable 2000 lb Gantry Crane | Heavy-Duty & AdjustableNewsAug.30,2025

-

Versatile Lifting Solutions with Gantry and Overhead CranesNewsAug.29,2025

-

The Versatile Mobile Gantry Crane SolutionNewsAug.29,2025

-

Reliable Movement with Heavy Machinery Skates and RollersNewsAug.29,2025

-

Reliable Lifting Performance with 2000 lb Gantry Crane and 2 Ton Overhead SystemsNewsAug.29,2025