জানু. . 31, 2025 01:34

Back to list

lifting magnet 100kg

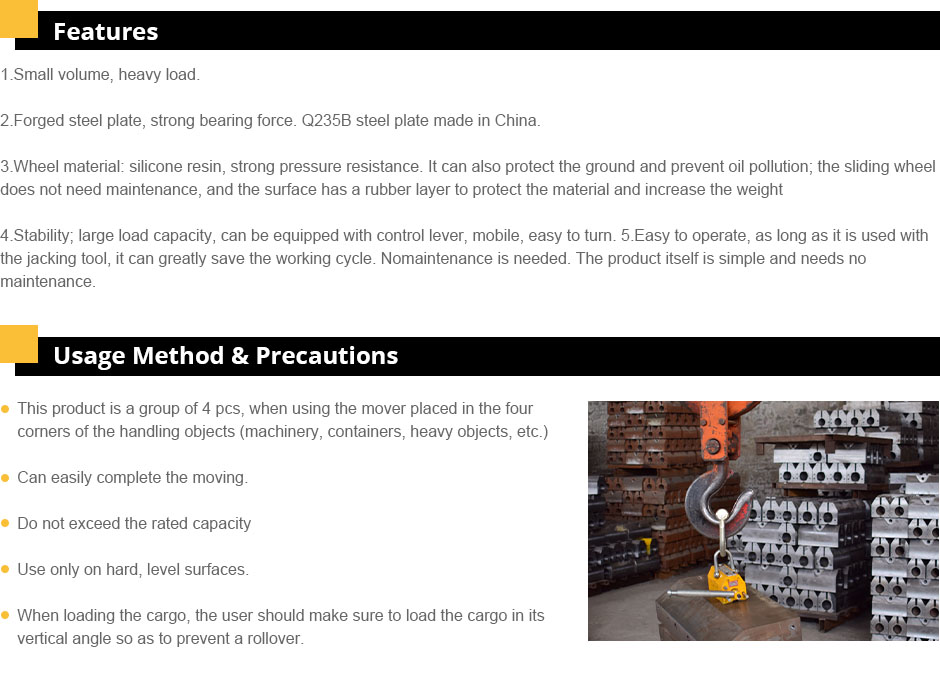

In the ever-evolving landscape of manufacturing and warehousing, the lifting magnet, particularly the 100kg capacity model, stands out as an indispensable tool in material handling. Exploring this equipment through firsthand experience reveals its extensive impact on efficiency and safety in the workplace.

Trustworthiness is a cornerstone of lifting magnet operations, particularly when handling loads weighing up to 100kg. Ensuring this attribute involves regular inspection routines and adherence to manufacturer-recommended maintenance schedules. This practice has been instilled in our operational protocol, leading to a notable reduction in downtime and operational hiccups. Testimonials from industry peers underscore the magnet's reputation, with many operators commending its consistency and safety features, such as built-in failsafes that prevent unexpected drops. A shared sentiment among experts is the transformative effect of leveraging lifting magnets in day-to-day operations. In a recent discussion with fellow industry veterans at a material handling expo, the consensus was clear lifting magnets not only streamline processes but also contribute significantly to workplace safety and morale. Their quiet operation and minimal footprint compared to mechanical hoists make them a preferred choice in space-constrained environments. In conclusion, the lifting magnet 100kg model epitomizes excellence in material handling. Its balance of innovative design, robust safety features, and compliance with industry standards establishes it as a trusted solution in the field. For businesses aiming to enhance operational efficiency while ensuring safety, investing in a quality lifting magnet is a step towards transformative industrial practices. By adopting such equipment, industries are not just optimizing material handling but are also paving the way for a safer, more productive future.

Trustworthiness is a cornerstone of lifting magnet operations, particularly when handling loads weighing up to 100kg. Ensuring this attribute involves regular inspection routines and adherence to manufacturer-recommended maintenance schedules. This practice has been instilled in our operational protocol, leading to a notable reduction in downtime and operational hiccups. Testimonials from industry peers underscore the magnet's reputation, with many operators commending its consistency and safety features, such as built-in failsafes that prevent unexpected drops. A shared sentiment among experts is the transformative effect of leveraging lifting magnets in day-to-day operations. In a recent discussion with fellow industry veterans at a material handling expo, the consensus was clear lifting magnets not only streamline processes but also contribute significantly to workplace safety and morale. Their quiet operation and minimal footprint compared to mechanical hoists make them a preferred choice in space-constrained environments. In conclusion, the lifting magnet 100kg model epitomizes excellence in material handling. Its balance of innovative design, robust safety features, and compliance with industry standards establishes it as a trusted solution in the field. For businesses aiming to enhance operational efficiency while ensuring safety, investing in a quality lifting magnet is a step towards transformative industrial practices. By adopting such equipment, industries are not just optimizing material handling but are also paving the way for a safer, more productive future.

Next:

Latest news

-

the-power-of-trolley-cargo-and-machinery-moving-solutionsNewsAug.22,2025

-

exploring-magnetic-lifting-devices-for-efficient-steel-plate-handlingNewsAug.22,2025

-

the-essential-guide-toportal-craneNewsAug.22,2025

-

enhancing-efficiency-in-permanent-magnetic-liftersNewsAug.22,2025

-

heavy-duty-machinery-movers-and-material-handling-solutionsNewsAug.22,2025

-

the-comprehensive-guide-to-adjustable-gantry-cranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025