mobile lifting gantry

Understanding Mobile Lifting Gantries Versatility in Lifting Solutions

Mobile lifting gantries have become indispensable tools in various industries, particularly in construction, manufacturing, and maintenance sectors. These portable lifting systems offer flexibility, ease of use, and can significantly enhance productivity when it comes to lifting and moving heavy loads. In this article, we will delve into the features, applications, benefits, and best practices associated with mobile lifting gantries.

What is a Mobile Lifting Gantry?

A mobile lifting gantry is a structure that provides a framework for hoisting loads using a lifting mechanism such as a crane or hoist. Typically constructed from materials like aluminum or steel, these gantries consist of an A-frame design that can be adjusted for height and span, allowing for the lifting of loads from various positions. The mobility aspect comes from wheels or casters mounted on the base, enabling easy transportation across job sites or within warehouses.

Features of Mobile Lifting Gantries

1. Adjustability Most mobile lifting gantries come with adjustable heights, allowing professionals to adapt the equipment based on the specific requirements of the job. This flexibility is advantageous in environments where loads of varying heights need to be lifted.

2. Portability Their lightweight construction and integrated wheels make it easy to move these gantries from one location to another. This portability is particularly valuable in large job sites or industries with dynamic workspaces.

3. Load Capacity Mobile lifting gantries can handle a significant range of load capacities, typically between 500 to 5,000 pounds, depending on the model. This wide load range caters to a variety of lifting applications, from small components to large machinery.

4. Compatibility These gantries can accommodate different types of hoisting equipment, including electric or manual chain hoists, making them versatile tools for various lifting needs.

Applications of Mobile Lifting Gantries

Mobile lifting gantries are utilized across many sectors due to their flexibility and efficiency. Some common applications include

1. Manufacturing In manufacturing plants, gantries are used for assembly line operations, machinery installation, and maintenance tasks. Their adjustable nature allows workers to lift heavy components to the desired height while maintaining safety.

2. Construction Construction sites frequently employ mobile lifting gantries to lift materials and equipment, such as beams, HVAC units, or heavy tools, into position without requiring a fixed overhead crane.

3. Maintenance In environments such as warehouses and distribution centers, these gantries facilitate the maintenance of large equipment and machinery by providing a safe and efficient way to lift and maneuver components into place.

mobile lifting gantry

Benefits of Using Mobile Lifting Gantries

1. Increased Efficiency With the ability to easily move heavy loads, these gantries eliminate the need for multiple workers to lift objects, significantly improving operational efficiency.

2. Enhanced Safety By providing a secure means of lifting, mobile lifting gantries reduce the risk of injury caused by manual handling. When used correctly, they can mitigate accidents associated with heavy lifting.

3. Cost-Effectiveness Their affordability compared to permanent lifting systems makes mobile lifting gantries a cost-effective solution for businesses that require occasional lifting capabilities without a long-term investment.

Best Practices for Using Mobile Lifting Gantries

To maximize the benefits of mobile lifting gantries while ensuring safety, operators should follow best practices

1. Regular Inspections Routine checks on the gantry’s structure and lifting mechanisms help ensure safety and performance.

2. Proper Training Operators should receive adequate training to understand how to use the gantry correctly, including load limits and proper lifting techniques.

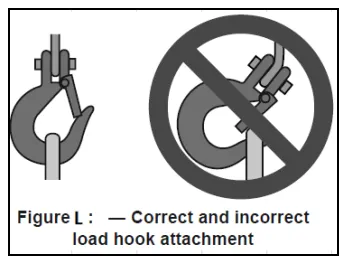

3. Weight Distribution Properly distributing the weight of the load on the gantry and using the right lifting equipment is crucial for safe operations.

4. Follow Manufacturer Guidelines Always adhere to recommended specifications provided by the manufacturer regarding load limits and assembly instructions.

Conclusion

Mobile lifting gantries offer a versatile, safe, and efficient means of managing heavy loads in a variety of environments. By understanding their features, applications, and benefits, industries can leverage these lifting solutions to enhance productivity and maintain safety on the job. As technology advances, we can anticipate further improvements in the design and functionality of mobile lifting gantries, making them an even more valuable asset in lifting operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025