Feb . 15, 2025 23:19

Back to list

overhead gantry

Overhead gantries are indispensable in modern industrial and commercial settings, playing a crucial role in enhancing operational efficiency and safety. These robust structures, either stationary or mobile, are designed to support and accommodate heavy equipment and materials, thereby optimizing workflow. Understanding the intricacies of overhead gantries can significantly benefit businesses seeking to improve their industrial processes and ensure workplace safety.

From a trustworthiness perspective, the supplier's reputation is a critical factor. Transparent communication regarding the manufacturing processes, material sourcing, and post-installation support services is vital in building confidence. Detailed documentation, comprehensive training for operators, and excellent customer service are trust-enhancing practices suppliers can offer. A trustworthy supplier will assist with both the technical and practical aspects of gantry implementation, minimizing potential operational disruptions and maintaining high safety levels. For businesses considering the integration of overhead gantries, shared industry experiences underline the importance of customization according to specific needs. Each industrial setting poses unique challenges, whether it involves constraints related to space, the nature of materials handled, or environmental considerations such as humidity and temperature. Assessment and customization based on these needs secure enhanced productivity gains and mitigate safety risks. Real-world applications of overhead gantries demonstrate their critical role in sectors such as manufacturing, logistics, and construction. For instance, operations in automobile manufacturing plants leverage gantries to efficiently move heavy engine components, while construction sites utilize them for the safe and swift transportation of construction materials. These applications highlight the broad spectrum of gantries' utility, underscoring the necessity for expertise, authoritative guidance, and reliable partnership with gantry providers. In conclusion, the decision to implement an overhead gantry system involves considerations of experience, expertise, authoritativeness, and trustworthiness. Viewing overhead gantries not as mere structural elements, but as strategic assets, empowers businesses to optimize their operations. By engaging with experts and authoritative manufacturers, businesses can achieve a blend of innovation, safety, and efficiency paramount to maintaining competitive and safe work environments.

From a trustworthiness perspective, the supplier's reputation is a critical factor. Transparent communication regarding the manufacturing processes, material sourcing, and post-installation support services is vital in building confidence. Detailed documentation, comprehensive training for operators, and excellent customer service are trust-enhancing practices suppliers can offer. A trustworthy supplier will assist with both the technical and practical aspects of gantry implementation, minimizing potential operational disruptions and maintaining high safety levels. For businesses considering the integration of overhead gantries, shared industry experiences underline the importance of customization according to specific needs. Each industrial setting poses unique challenges, whether it involves constraints related to space, the nature of materials handled, or environmental considerations such as humidity and temperature. Assessment and customization based on these needs secure enhanced productivity gains and mitigate safety risks. Real-world applications of overhead gantries demonstrate their critical role in sectors such as manufacturing, logistics, and construction. For instance, operations in automobile manufacturing plants leverage gantries to efficiently move heavy engine components, while construction sites utilize them for the safe and swift transportation of construction materials. These applications highlight the broad spectrum of gantries' utility, underscoring the necessity for expertise, authoritative guidance, and reliable partnership with gantry providers. In conclusion, the decision to implement an overhead gantry system involves considerations of experience, expertise, authoritativeness, and trustworthiness. Viewing overhead gantries not as mere structural elements, but as strategic assets, empowers businesses to optimize their operations. By engaging with experts and authoritative manufacturers, businesses can achieve a blend of innovation, safety, and efficiency paramount to maintaining competitive and safe work environments.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

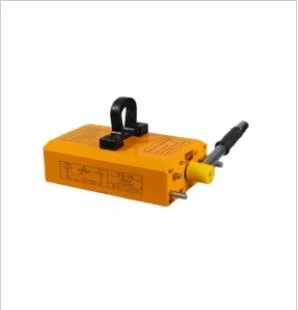

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025