Design and Analysis of Crane Gantry Girder Systems for Efficient Material Handling

The Crane Gantry Girder An Essential Component in Modern Industries

In the world of heavy lifting and material handling, crane gantry girders play a pivotal role in enabling effective and efficient operations. Understanding the purpose, design, and applications of crane gantry girders can provide insights into how modern industries handle heavy loads with precision and safety.

A crane gantry girder is a key structural element that supports the movement of cranes in various industrial applications. Typically constructed from steel, these girders are designed to bear significant loads while providing stability and durability. They are characterized by their robust framework, which is essential for the crane’s functionality. The gantry girder is fixed on legs or a frame that elevates it above the ground, allowing for the movement of the crane along a specific track. This design is particularly beneficial in applications where space is limited or where fixed cranes are not feasible.

The primary function of a crane gantry girder is to support the hoisting mechanisms of the crane. This includes the trolley and hoist system that can lift and move heavy materials. The design of the gantry girder must take into account various factors such as load capacity, span length, and the operational environment. For example, indoor gantry cranes may have different design specifications compared to outdoor models that need to withstand environmental factors like rain, wind, and temperature fluctuations.

In terms of design, crane gantry girders come in various configurations, including single girder and double girder systems. A single girder gantry crane features one horizontal beam supported by two vertical legs, making it suitable for lighter loads and shorter spans. On the other hand, a double girder gantry crane comprises two parallel beams, providing increased strength and stability, which is ideal for heavier loads and longer spans. The choice between these configurations often depends on the specific requirements of the task at hand.

crane gantry girder

One of the most significant advantages of using crane gantry girders is their versatility. They can be used in a myriad of applications, from manufacturing plants and warehouses to shipyards and construction sites. For instance, in manufacturing environments, gantry cranes are utilized to move raw materials between production stations, enhancing workflow efficiency. In construction, they are vital for hoisting heavy equipment and materials, proving indispensable for large-scale projects.

Safety is a primary consideration in the design and operation of gantry cranes. Engineers must ensure that the gantry girders are built to withstand not just the weight of the loads they will carry but also the dynamic forces encountered during operations. This includes factors like sudden stops and starts, wind loads, and vibrations. Safety features such as limit switches, emergency stop buttons, and overload protection systems are also critical in preventing accidents.

In recent years, advancements in technology have further enhanced the functionality of crane gantry girders. Automation and telematics integration have allowed for smarter operations, with features such as remote control, real-time monitoring of loads, and predictive maintenance capabilities. These innovations not only improve efficiency but also significantly enhance safety and reduce the likelihood of human error during operations.

Moreover, the materials used in the construction of crane gantry girders have evolved. Modern materials not only provide greater strength but also reduce weight, leading to increased energy efficiency during operation. The introduction of high-strength steels and composite materials has enabled the construction of lighter and more durable girders, capable of handling demanding workloads.

In conclusion, crane gantry girders are crucial elements in the framework of modern logistics and construction. Their strength, versatility, and safety features make them indispensable for various industrial applications. As technology continues to advance, the design and functionality of these critical components are likely to evolve, paving the way for even more innovative solutions in material handling and lifting operations. Understanding the role of gantry girders can provide valuable insights into the operational efficiencies and safety protocols that define contemporary industrial landscapes.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

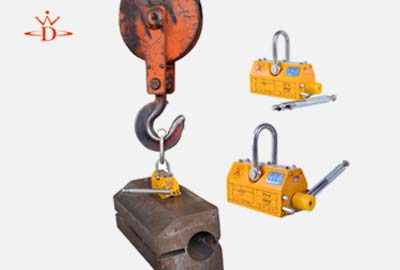

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025