magnetic hand lifter

Understanding Magnetic Hand Lifters A Key Tool for Material Handling

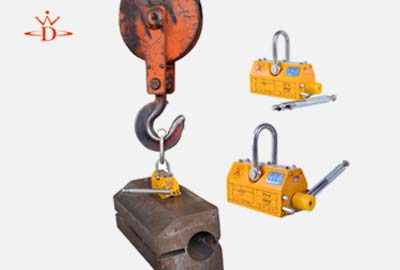

In the realm of industrial machinery and material handling, the importance of efficient and safe lifting equipment cannot be overstated. Among the various tools available, the magnetic hand lifter stands out as a particularly effective solution for transporting ferrous materials. Utilizing powerful magnets, these devices simplify the process of lifting heavy metal objects, making them invaluable in construction sites, warehouses, and manufacturing facilities.

What is a Magnetic Hand Lifter?

A magnetic hand lifter is a portable device designed primarily to lift and transport ferrous (iron-containing) materials. It typically consists of a robust body, a strong permanent magnet, a handle for operation, and a release mechanism. The main advantage of using a magnetic lifter is its ability to lift objects quickly and securely, without the need for hooks, chains, or slings that are often cumbersome and time-consuming to use.

How Do Magnetic Hand Lifters Work?

The operation of a magnetic hand lifter is relatively straightforward. When the lifter is placed on a metallic surface, the permanent magnets are activated. These magnets generate a strong magnetic field that adheres to the metal, allowing the lifter to hold and carry the object securely. The release mechanism is designed to deactivate the magnetic field, enabling the safe release of the load once it reaches its destination.

The lifting capacity of these devices can vary significantly based on their design and manufacturing quality. Some are capable of lifting hundreds of pounds, making them suitable for various heavy-duty applications.

Benefits of Using Magnetic Hand Lifters

1. Efficiency Magnetic hand lifters can dramatically increase productivity in material handling operations. They allow workers to lift and move heavy objects quickly, reducing the time required for loading and unloading tasks.

magnetic hand lifter

2. Safety The design of magnetic lifters minimizes the risk of accidents commonly associated with lifting heavy items. Traditional lifting methods often involve the risk of slippage or failure of chains and slings, whereas magnetic lifters offer a secure grip on ferrous materials.

3. Versatility These lifters can be used on various surfaces and for different shapes and sizes of metal objects, including plates, sheets, and even pipes. This versatility makes them a staple in many industrial settings.

4. Cost-Effectiveness By improving efficiency and reducing injury-related costs, magnetic hand lifters can lead to significant savings over time. Additionally, their durability means they can withstand harsh working environments, thereby reducing the need for frequent replacements.

5. Ease of Use Magnetic lifters are generally user-friendly. With minimal training, operators can learn to handle these devices effectively, contributing to a smooth workflow.

Applications of Magnetic Hand Lifters

Magnetic hand lifters are widely used across various industries. In manufacturing, they are essential for moving metal parts during assembly. In warehousing, they assist in organizing inventory by moving heavy pallets and containers. Construction sites benefit from magnetic lifters when handling steel beams and plates. Additionally, they are utilized in scrap yards for sorting and transporting ferrous scrap metal.

Conclusion

Magnetic hand lifters represent a remarkable advancement in material handling technology. Their ability to lift heavy ferrous objects efficiently and safely makes them indispensable for numerous industries. As businesses continue to seek ways to improve efficiency and safety in their operations, the magnetic hand lifter stands out as a practical solution. Investing in this tool not only enhances productivity but also contributes to creating a safer work environment. Whether in manufacturing, construction, or warehousing, magnetic hand lifters are a wise choice for any organization looking to optimize their material handling process.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025