moving big equipment

Moving Big Equipment Challenges and Solutions

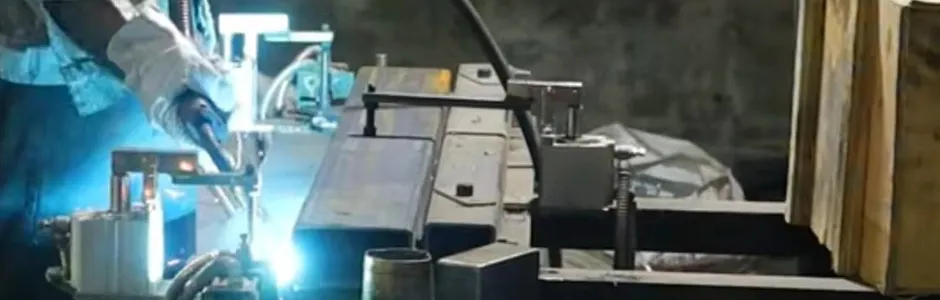

Moving big equipment is a complex task that requires careful planning, specialized knowledge, and the right tools. Whether it’s relocating heavy machinery, industrial robots, or construction equipment, each move presents its own unique set of challenges. Companies involved in this industry must navigate a maze of logistics, safety regulations, and technical specifications. This article outlines the key challenges in moving big equipment and presents some effective solutions.

Challenges

1. Weight and Size Limitations Large equipment typically weighs several tons and can be oversized, making transportation problematic. Standard vehicles may not be equipped to handle heavy loads. Moreover, the overall size can restrict access to certain roads and facilities, especially in urban areas.

2. Logistical Coordination Planning the route for moving heavy machinery involves detailed mapping of the journey, considering factors such as road conditions, weight limits on bridges, and any necessary permits. Coordinating with local authorities to secure permits is crucial, but it can be a time-consuming process.

3. Safety Concerns The safety of both the workers involved in the move and the public is paramount. Heavy equipment can pose risks, including tipping, sliding, or even causing traffic accidents if not properly secured. Additionally, the setup and dismantling phases can also lead to injuries or damages.

4. Cost Implications Moving big equipment can be expensive. The costs associated with transportation, labor, insurance, and permits can add up quickly. Companies must weigh the benefits of moving equipment against the financial burden it may impose.

Solutions

moving big equipment

1. Utilizing Specialized Transport The use of specialized transport vehicles designed to carry heavy loads is essential. Lowboy trailers, flatbeds, and hydraulic transporters can significantly improve the efficiency and safety of the move. These vehicles can accommodate the size and weight of big equipment while ensuring stability during transit.

2. Professional Expertise Hiring a professional logistics company that specializes in moving heavy machinery can alleviate most challenges associated with the task. These experts are well-versed in the intricacies of securing permits, planning routes, and implementing safety measures. Their experience can prevent costly mistakes and delays.

3. Rigging and Heavy Lifting Equipment Proper rigging techniques and heavy-lifting equipment, such as cranes, can be crucial for safely loading and unloading large machinery. Using certified riggers and equipment ensures that the move is conducted safely and effectively.

4. Thorough Planning Developing a comprehensive plan that considers all aspects of the move is vital. This includes creating timelines, identifying potential obstacles, and preparing contingency plans for unexpected issues. A well-thought-out plan minimizes risks and ensures smooth execution.

5. Safety Training Providing safety training for all personnel involved in the move is crucial. Workers need to understand best practices for handling heavy equipment, including how to safely operate machinery during transport and how to respond in case of an emergency.

Conclusion

Moving big equipment is not a task to be taken lightly. The challenges involved require careful consideration and professional management. With the right planning, specialized tools, and expert assistance, companies can successfully navigate the complexities of relocating heavy machinery. Ultimately, prioritizing safety and efficiency can lead to a successful move, minimizing downtime and maximizing productivity.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025