Powerful Magnetic Plate Lifter for Efficient Handling of Heavy Metal Objects

The Magnetic Plate Lifter An Essential Tool in Modern Industry

In today's fast-paced industrial landscape, efficiency and safety are paramount. One device that has become indispensable in various sectors is the magnetic plate lifter. This innovative tool is engineered to lift and transport ferrous metal plates with ease, significantly enhancing productivity while reducing the risk of injury.

Understanding Magnetic Plate Lifters

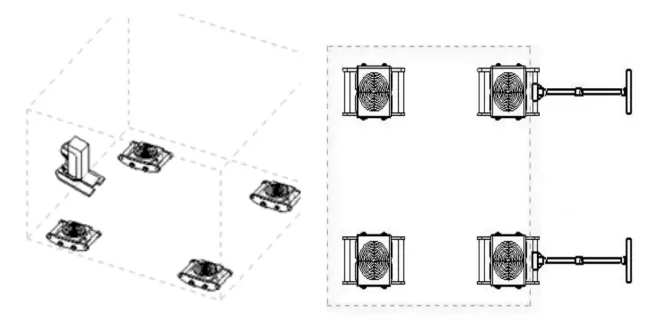

A magnetic plate lifter operates on the principle of magnetism. It uses powerful electromagnetic forces to securely grip metal objects, making it an ideal solution for lifting heavy steel plates, sheets, and blocks. When activated, the electromagnet generates a strong magnetic field that adheres to the material, allowing the user to transport it without the need for additional chains, hooks, or slings. This streamlined approach minimizes the chance of accidents and improves the overall workflow in manufacturing and construction environments.

Applications in Industry

The applications of magnetic plate lifters are vast. They are widely used in manufacturing facilities, metalworking shops, and warehouses, where they facilitate the handling of materials that would otherwise require multiple operators or heavy machinery. Industries such as automotive, aerospace, and construction employ these lifters for tasks ranging from moving raw materials to assembling intricate components.

For example, in an automotive manufacturing plant, a magnetic plate lifter can quickly and safely position steel plates and parts onto assembly lines. This not only speeds up production but also ensures a safer working environment, as workers are less likely to suffer injuries from lifting heavy items manually. Similarly, in the construction industry, these lifters can expedite the handling of steel beams and plates, contributing to more efficient project completion times.

Safety Benefits

Safety is a critical consideration when it comes to handling heavy materials. Traditional lifting methods often involve significant risk, including strains, sprains, and accidents due to dropped loads. Magnetic plate lifters address these concerns by reducing manual handling. Their design typically includes features such as automatic power shut-off and easy-to-use controls, allowing operators to concentrate on the task without worrying about the load slipping or falling.

magnetic plate lifter

Moreover, many models are equipped with safety indicators that signal whether the lifter is securely attached to the load, providing an additional layer of reassurance before movement. This focus on safety is crucial, especially in environments where multiple operators are working around heavy equipment.

Key Features to Consider

When selecting a magnetic plate lifter, there are several key features to consider

1. Weight Capacity Different models have varying lifting capacities, so it’s essential to choose one that meets the specific needs of your operation. 2. Magnetic Strength This determines how securely the lifter can hold onto the material. A stronger magnet allows for safer operation with heavier loads. 3. Power Source Electromagnetic lifters require a power source to function. Consider whether a battery-operated or a plug-in model best suits your environment.

4. Portability Depending on your application's mobility needs, a lighter and more portable design might be advantageous.

5. Safety Features Look for lifters with built-in safety features such as overload protection, automatic shut-off, and visual load indicators to enhance operational safety.

Conclusion

In conclusion, magnetic plate lifters are a vital asset in the modern industrial toolkit. They not only improve the efficiency of material handling but also enhance safety measures in workplaces where heavy lifting is routine. By integrating magnetic lifters into your operations, you can streamline workflows, reduce labor costs, and create a safer environment for workers. Whether in manufacturing, construction, or warehousing, these tools represent a significant leap forward in how industries manage heavy materials. Their benefits are hard to overlook, making them a sound investment for any business looking to optimize its operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025