Feb . 16, 2025 00:34

Back to list

overhead travelling crane

Overhead travelling cranes have long been the backbone of industries where heavy lifting is a routine operation. These engineering marvels seamlessly combine precision, strength, and efficiency to tackle tasks that manual labor simply cannot achieve. Their dominance in domains ranging from manufacturing to construction underscores their indispensable role in modern production environments.

Moreover, industry experts have underscored the environmentally sustainable adaptations of modern overhead travelling cranes. Improved energy efficiency through regenerative drives, use of lighter yet stronger materials, and integration of renewable energy sources reflect the industry’s commitment to reducing its carbon footprint. This transition not only aligns with global sustainability goals but also promises cost savings, making these cranes a favored choice in green-certified infrastructures. For professionals in industries heavily reliant on these cranes, operator training is a testament to the weightage given to experience. Mastery over crane operations involves understanding complex control systems, awareness of safety protocols, and responsiveness to environmental cues. Experienced operators can maneuver loads deftly, minimizing downtime and material damage, which adds significant value to operational processes. Companies investing in overhead travelling cranes must also consider the implications of installation and setup. Customization to fit specific operational demands is a common requirement. This involves a consultation process where experts assess facility layouts and production workflows to recommend crane systems that maximize efficiency and safety. The expertise of installation teams ensures that these heavy machines are integrated seamlessly into existing operations with minimal disruption. The lifecycle of an overhead travelling crane—spanning design through to decommissioning—exemplifies engineering at its pinnacle. Manufacturers are continually refining designs to align with evolving industrial demands, addressing challenges posed by heavier loads, tighter spaces, and faster production lines. Choosing the right crane requires due diligence, evaluating parameters such as lift capacity, crane span, lifting speed, and the intricacies of operational environments. Ultimately, overhead travelling cranes are more than just mechanical aids; they are strategic assets that influence production efficiency and safety standards. Their significance in industrial operations extends beyond immediate functional benefits, contributing enduringly to operational workflows, cost management, and sustainable industrial solutions. It is this multifaceted impact that makes them a cornerstone of modern industry and an area of continual development and expertise.

Moreover, industry experts have underscored the environmentally sustainable adaptations of modern overhead travelling cranes. Improved energy efficiency through regenerative drives, use of lighter yet stronger materials, and integration of renewable energy sources reflect the industry’s commitment to reducing its carbon footprint. This transition not only aligns with global sustainability goals but also promises cost savings, making these cranes a favored choice in green-certified infrastructures. For professionals in industries heavily reliant on these cranes, operator training is a testament to the weightage given to experience. Mastery over crane operations involves understanding complex control systems, awareness of safety protocols, and responsiveness to environmental cues. Experienced operators can maneuver loads deftly, minimizing downtime and material damage, which adds significant value to operational processes. Companies investing in overhead travelling cranes must also consider the implications of installation and setup. Customization to fit specific operational demands is a common requirement. This involves a consultation process where experts assess facility layouts and production workflows to recommend crane systems that maximize efficiency and safety. The expertise of installation teams ensures that these heavy machines are integrated seamlessly into existing operations with minimal disruption. The lifecycle of an overhead travelling crane—spanning design through to decommissioning—exemplifies engineering at its pinnacle. Manufacturers are continually refining designs to align with evolving industrial demands, addressing challenges posed by heavier loads, tighter spaces, and faster production lines. Choosing the right crane requires due diligence, evaluating parameters such as lift capacity, crane span, lifting speed, and the intricacies of operational environments. Ultimately, overhead travelling cranes are more than just mechanical aids; they are strategic assets that influence production efficiency and safety standards. Their significance in industrial operations extends beyond immediate functional benefits, contributing enduringly to operational workflows, cost management, and sustainable industrial solutions. It is this multifaceted impact that makes them a cornerstone of modern industry and an area of continual development and expertise.

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

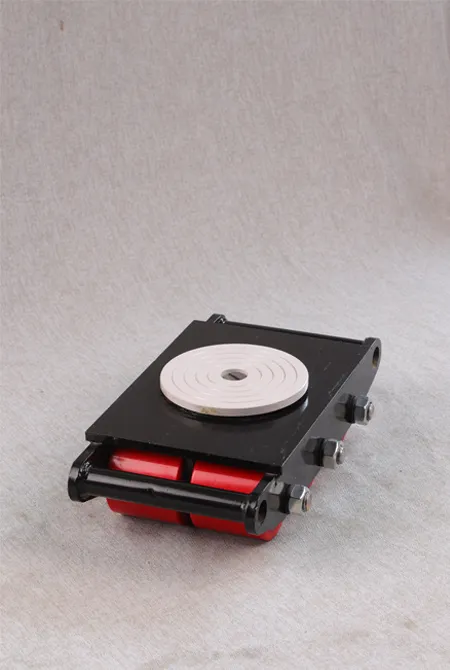

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025