1 tonne lifting gantry

Exploring the Versatility of the 1% Tonne Lifting Gantry

In the realm of heavy lifting and material handling, the 1% tonne lifting gantry serves as a remarkable piece of equipment designed to streamline operations across various industries. This versatile gantry system is engineered to provide efficient lifting solutions for tasks that require precision, safety, and reliability. Understanding its features and applications can shed light on why it has become an essential tool in modern workplaces.

Exploring the Versatility of the 1% Tonne Lifting Gantry

One of the key advantages of the 1% tonne lifting gantry is its ease of use. Most models are lightweight and portable, which means they can be easily maneuvered into position without the need for extensive training or elaborate setup processes. Furthermore, many gantries come equipped with manual or electric hoisting mechanisms, facilitating smoother and faster lifting operations. This user-friendly approach not only enhances productivity but also significantly reduces the likelihood of accidents—an essential factor in heavy lifting scenarios.

1 tonne lifting gantry

The safety features of the 1% tonne lifting gantry cannot be overstated. With the potential for lifting heavy loads, the risk of accidents is always a concern. Most gantries are designed with features such as locking mechanisms, robust frame construction, and overload protection systems. These elements work together to ensure that both operators and bystanders are protected during lifting operations. Regular maintenance and inspection protocols further enhance safety, allowing companies to uphold high standards while minimizing potential risks.

In terms of applications, the 1% tonne lifting gantry is incredibly versatile. It is widely used in manufacturing for assembling and moving heavy machinery, as well as in construction for lifting materials and installing structural components. The automotive industry also benefits from gantry systems for engine lifts and vehicle assembly processes. Beyond industrial applications, even smaller sectors like HVAC installation and event setup can take advantage of this equipment for heavy lifting tasks.

Moreover, the growing emphasis on efficiency and automation in workplaces is driving innovations within lifting gantry technologies. Recent advancements include integrated digital load monitoring systems, remote controls, and enhanced portability. These features not only contribute to improved operational efficiency but also cater to the evolving needs of modern industries.

In conclusion, the 1% tonne lifting gantry represents an indispensable solution for various lifting applications in today’s industrial landscape. Its versatility, safety features, and ease of use make it an attractive option for businesses looking to optimize their material handling processes. As industries continue evolving, so too will the technology surrounding lifting solutions, ensuring that equipment like the 1% tonne lifting gantry remains at the forefront of heavy lifting innovation. Whether for routine tasks or specialized operations, this equipment is poised to play a critical role in the efficiency and safety of material handling practices.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

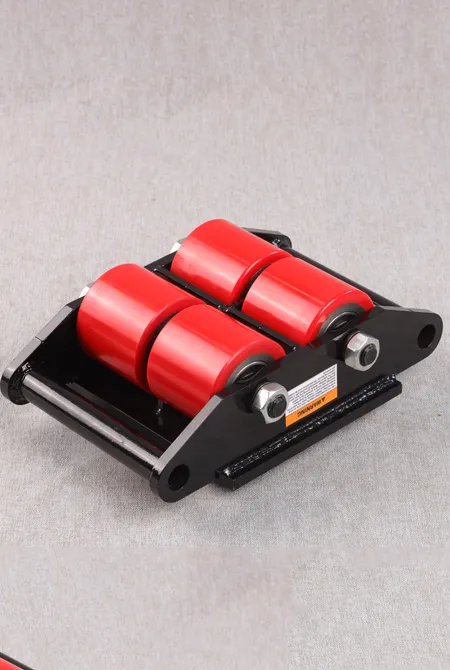

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025