Powerful 1 Ton Lifting Magnet for Heavy Duty Industrial Applications and Efficient Handling

Exploring the Power and Versatility of 1% Ton Lifting Magnets

Lifting magnets have become indispensable tools in various industries, providing an efficient and safe means to move heavy ferromagnetic materials. Among these innovative tools, the 1% ton lifting magnet holds a special place due to its versatility and effectiveness. This article delves into the characteristics, applications, and benefits of 1% ton lifting magnets, highlighting their significance in modern industry.

Understanding 1% Ton Lifting Magnets

A lifting magnet is a device that uses magnetic force to lift, hold, or move ferromagnetic materials such as steel plates, pipes, and other metal objects. The term 1% ton lifting magnet refers to a magnet with the capacity to lift items weighing up to one ton, making it an ideal solution for various lifting tasks. These magnets utilize a combination of electromagnetism and advanced engineering to provide reliable performance in demanding environments.

How They Work

1% ton lifting magnets typically operate on the principle of electromagnetism. When an electric current flows through the coil of wire wrapped around the magnet, it generates a magnetic field that attracts ferromagnetic materials. Some lifting magnets are permanent magnets, using neodymium or ferrite materials, while others are electromagnets that require a power source to generate the magnetic field.

The design of these magnets often includes a safety mechanism to ensure that the magnetic force remains strong and reliable under load. Many models feature an easy-to-use control system, allowing operators to turn the magnet on or off with minimal effort.

Applications Across Industries

The applications of 1% ton lifting magnets are extensive and span several industries, including manufacturing, construction, shipping, and recycling.

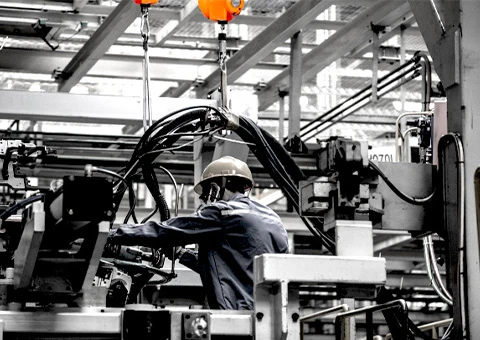

1. Manufacturing In factories, these magnets are frequently employed for moving heavy metal sections during the fabrication process. They can streamline operations by efficiently lifting and positioning components, leading to increased productivity and reduced labor costs.

1 ton lifting magnet

2. Construction Construction sites often utilize lifting magnets for hoisting steel beams and reinforcements. Their ability to grip large, heavy materials securely allows for safer and quicker assembly of structures, minimizing the reliance on hoists or cranes.

3. Shipping and Logistics In warehouses and shipping yards, lifting magnets facilitate the loading and unloading of cargo. They can quickly and safely pick up metal containers, reducing the risk of injury that comes with manual handling.

4. Recycling The recycling industry benefits enormously from 1% ton lifting magnets, which are used to sort and move scrap metal efficiently. They can easily collect large quantities of metallic waste, promoting sustainability and recycling efforts.

Benefits of Using 1% Ton Lifting Magnets

The advantages of using 1% ton lifting magnets are numerous. One of the most significant benefits is the efficiency they bring to operations. By reducing the need for manual lifting, these magnets save time and minimize the risk of worker injuries, leading to enhanced workplace safety.

Moreover, lifting magnets are often more cost-effective compared to traditional lifting equipment. They require less maintenance and have fewer mechanical parts that could fail over time, thereby decreasing operational costs. The compact design of many 1% ton lifting magnets also allows for easy storage and maneuverability in confined spaces.

Lastly, their adaptability allows them to be used in various settings with different materials, making them an invaluable asset across diverse applications.

Conclusion

In conclusion, the 1% ton lifting magnet exemplifies innovation in lifting technology. Its ability to safely and effectively handle heavy materials makes it a vital tool in industries ranging from manufacturing to recycling. As work processes evolve and industries push towards greater efficiency and safety, the significance of lifting magnets will undoubtedly continue to grow. Investing in such technological advancements will pave the way for more effective and safer working environments, unlocking new potential for businesses worldwide.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025