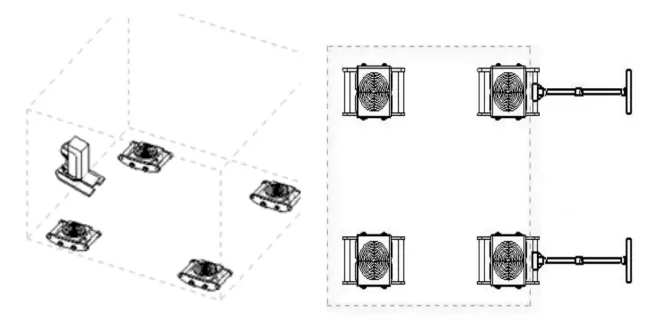

1 ton lifting magnet

The Power and Versatility of 1% Ton Lifting Magnets

In the realm of industrial lifting and material handling, magnets have revolutionized the way heavy loads are moved and managed. Among various types of lifting equipment, the 1% ton lifting magnet stands out due to its impressive capacity, reliability, and versatility. This article delves into the features, applications, advantages, and considerations associated with 1% ton lifting magnets, emphasizing their significance in today's manufacturing and logistics environments.

Features of 1% Ton Lifting Magnets

A 1% ton lifting magnet is designed to handle loads weighing up to 1 ton (approximately 2,000 pounds). These magnets often utilize high-grade ferromagnetic materials and advanced electromagnet technology to ensure a powerful and consistent lifting capability. Many designs include a simple switch mechanism for easy operation, making them user-friendly and efficient in various settings.

The construction of these magnets usually incorporates robust safety features, such as adjustable lifting heights and automatic release mechanisms, which help prevent accidents during lifting operations. Additionally, many 1% ton lifting magnets are equipped with a durable coat of protective paint to withstand harsh industrial environments, including exposure to moisture, dust, and temperature fluctuations.

Applications in Various Industries

1% ton lifting magnets find applications across numerous industries, making them a crucial tool for effective material handling. Common sectors that benefit from their capabilities include

1. Manufacturing In manufacturing facilities, lifting magnets streamline the transportation of metal parts, sheets, and components. Their ability to hold and move large quantities of ferrous metal makes them indispensable in assembly lines, reducing manual labor and increasing overall productivity.

2. Construction Construction sites often require the movement of heavy steel beams and sheets. 1% ton lifting magnets facilitate the quick and safe relocation of these materials, allowing for efficient project timelines and reducing the risk of workplace injuries.

3. Scrap Metal Recycling The scrap metal industry benefits immensely from the application of 1% ton lifting magnets. These magnets make it easy to gather and transport ferrous materials, thereby speeding up the recycling process while ensuring that operations remain efficient and cost-effective.

4. Shipping and Warehousing In shipping and warehousing, lifting magnets enhance efficiency by allowing workers to quickly load and unload metal goods from trucks and containers. Their ability to lift heavy loads without the need for additional equipment simplifies the process and maximizes space.

1 ton lifting magnet

Advantages of Using 1% Ton Lifting Magnets

The adoption of 1% ton lifting magnets comes with several significant advantages. These benefits include

1. Increased Efficiency By utilizing magnetic forces to lift materials, lifting magnets dramatically reduce the time and effort required to handle heavy loads. This efficiency leads to shorter project timelines and increased throughput in various industries.

2. Enhanced Safety With fewer manual handling requirements, the risk of workplace injuries decreases significantly. The automated lifting mechanism reduces the chances of accidents that might occur with cranes or forklifts.

3. Cost-Effectiveness While the initial investment in a 1% ton lifting magnet might seem steep, the long-term savings in labor costs and improved productivity can offset this expense. Companies can achieve a higher return on investment due to reduced operational costs in the long run.

4. Versatility The versatility of 1% ton lifting magnets means that they can be utilized across a broad scope of applications. They can lift various shapes and sizes of metal objects, making them functional for numerous tasks within an operation.

Considerations and Best Practices

While 1% ton lifting magnets are advantageous, there are essential considerations to keep in mind. Users must ensure that the loads being lifted are compatible with the magnet's capacity to prevent potential accidents and equipment failures. Regular inspection and maintenance of the lifting magnets are also vital to ensure their continued efficiency and safety.

Additionally, training personnel on proper usage techniques and safety protocols is crucial. Workers must be familiar with the operational mechanics of lifting magnets to maximize their benefits and minimize risks.

Conclusion

The 1% ton lifting magnet is a powerful tool that enhances efficiency, safety, and versatility in material handling across various industries. By understanding their features, applications, and advantages, businesses can leverage these magnets to improve their operational capabilities significantly. As technology continues to advance, the role of lifting magnets in industrial applications will likely grow, positioning them as a cornerstone for efficient material handling solutions.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025