500kg gantry system for heavy lifting and precise industrial applications

Exploring the 500kg Gantry System Innovation in Material Handling

In the realm of engineering and industrial applications, the gantry system has emerged as a key player in enhancing efficiency and safety in material handling processes. Among the various specifications, the 500kg gantry system stands out due to its versatility and robust design. This article delves into the features, applications, and advantages of the 500kg gantry system, illustrating why it is a valuable asset in modern industrial settings.

A gantry system, in its simplest form, is a structure that consists of a framework to support hoists, cranes, or other lifting mechanisms. The 500kg designation indicates the maximum load capacity the gantry can safely handle, making it suitable for a wide range of lifting tasks. The design typically includes a rectangular frame that spans above the work area, supported by two legs at either end. This structure allows for the efficient transfer of materials across large distances, maximizing workspace utilization.

One of the primary benefits of a 500kg gantry system is its adaptability. Industries such as manufacturing, construction, and logistics all benefit from this versatile equipment. In manufacturing, for instance, the gantry can facilitate the movement of heavy machinery parts or components from one location to another, reducing the strain on workers and minimizing the risk of injury. This system also finds utility in construction sites, where it can lift heavy materials like steel beams or concrete blocks, streamlining the building process.

Safety is a critical aspect of any industrial application, and the 500kg gantry system is designed with numerous safety features

. Many models come equipped with limit switches, emergency stop buttons, and overload protection mechanisms to ensure that lifting operations remain secure. By utilizing such a system, employers can significantly reduce workplace accidents, creating a safer environment for their staff.500kg gantry

Moreover, the 500kg gantry system is often portable, allowing it to be easily relocated as needed. Many gantry systems are designed with adjustable heights, enabling users to modify the configuration according to the specific requirements of the task at hand. This flexibility ensures that a single system can serve multiple purposes over its lifespan, delivering a high return on investment.

In addition to physical benefits, the 500kg gantry system also contributes to improved productivity. The speed at which materials can be moved directly impacts project timelines. By utilizing a gantry system, businesses can significantly cut down on the time spent on manual handling, allowing staff to focus on more productive tasks. The efficient movement of materials not only boosts productivity but also enhances workflow and coordination among teams.

In recent years, advancements in technology have further augmented the capabilities of gantry systems. Many modern models incorporate smart features such as remote controls and integration with warehouse management systems, enabling more precise operations. These innovations facilitate real-time tracking and monitoring of materials, promoting an efficient and organized work environment.

In conclusion, the 500kg gantry system represents a vital tool in the arsenal of industrial equipment. Its blend of strength, versatility, safety, and efficiency makes it an indispensable asset in various sectors. As industries continue to evolve, the demand for innovative and efficient material handling solutions like the 500kg gantry system is only set to rise, driving advancements that will further enhance its functionality and application in the years to come. Investing in such systems not only modernizes operations but also contributes to a safer and more productive workplace.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

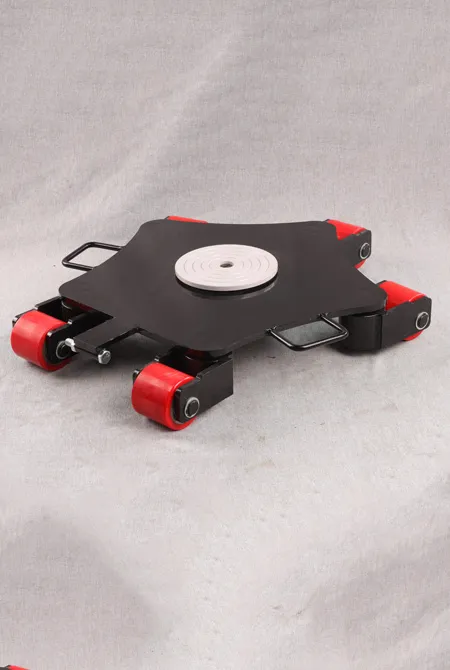

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025