Affordable 1 Ton Gantry Crane Cost Comparison for Various Industrial Applications and Projects

Understanding the Price of a 1% Ton Gantry Crane

Gantry cranes are essential pieces of equipment in industries where heavy lifting and material handling are required. They are particularly popular in warehouses, construction sites, and manufacturing facilities due to their versatility and ability to move materials efficiently. One common type is the 1% ton gantry crane, which is designed to lift loads weighing up to one ton. As with any industrial equipment, understanding the price factors associated with a 1% ton gantry crane is vital for businesses and operators looking to invest wisely.

Price Breakdown

The price of a 1% ton gantry crane can vary widely based on several factors, including the design, manufacturer, materials used, and additional features. On average, a standard gantry crane in this capacity range can cost between $2,000 to $10,000. However, customized models or those made from specialized materials may exceed this price range.

1. Design and Type Gantry cranes come in various designs, including portable, adjustable-height, and fixed models. A portable gantry crane, which is easy to relocate, may be priced higher due to its convenience. If the crane is adjustable to fit different working environments, its price may also increase.

2. Construction and Materials The materials used in constructing the gantry crane significantly impact its price. Cranes made from high-quality steel or aluminum tend to be more expensive because they offer greater durability and load capacity. The surface treatment, such as powder-coating or galvanization, also contributes to the cost by enhancing corrosion resistance.

3. Features and Technology Modern gantry cranes often come with advanced features such as electric hoists, remote control systems, and integrated safety mechanisms. These additions not only improve the efficiency of operations but also enhance safety. However, they add to the overall price of the crane.

4. Brand Reputation The reputation of the manufacturer plays a crucial role in pricing. Well-known brands with a history of reliability and quality assurance usually charge more due to their established market presence. Conversely, lesser-known or emerging brands might offer more competitive pricing, but customers should carefully consider the risks associated with lesser-known equipment.

1 ton gantry crane price

Additional Costs

In addition to the initial purchase price, there are other costs to consider when budgeting for a 1% ton gantry crane

- Shipping and Handling Depending on the size and weight of the crane, shipping costs can vary significantly. It’s essential to factor this into your total budget. - Installation Some gantry cranes require professional installation, which can add to the overall expenditure. It's advisable to consult with the manufacturer or supplier about installation services.

- Maintenance Regular maintenance is necessary to prolong the lifespan and performance of the gantry crane. Setting aside a budget for routine inspections and repairs is crucial.

- Operational Costs Don’t forget to consider the cost of electricity, if the crane utilizes electric-powered hoisting systems, as well as any personnel training required for effective operation.

Conclusion

A 1% ton gantry crane can be a significant investment for any business involved in heavy lifting and material handling. Understanding the various factors that influence the price—such as design, materials, features, and brand—can help potential buyers make informed decisions. Furthermore, accounting for additional costs associated with shipping, installation, maintenance, and operation ensures that you are fully prepared for the total cost of ownership. By carefully weighing these considerations, businesses can select the right gantry crane to enhance their operational efficiency and productivity.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

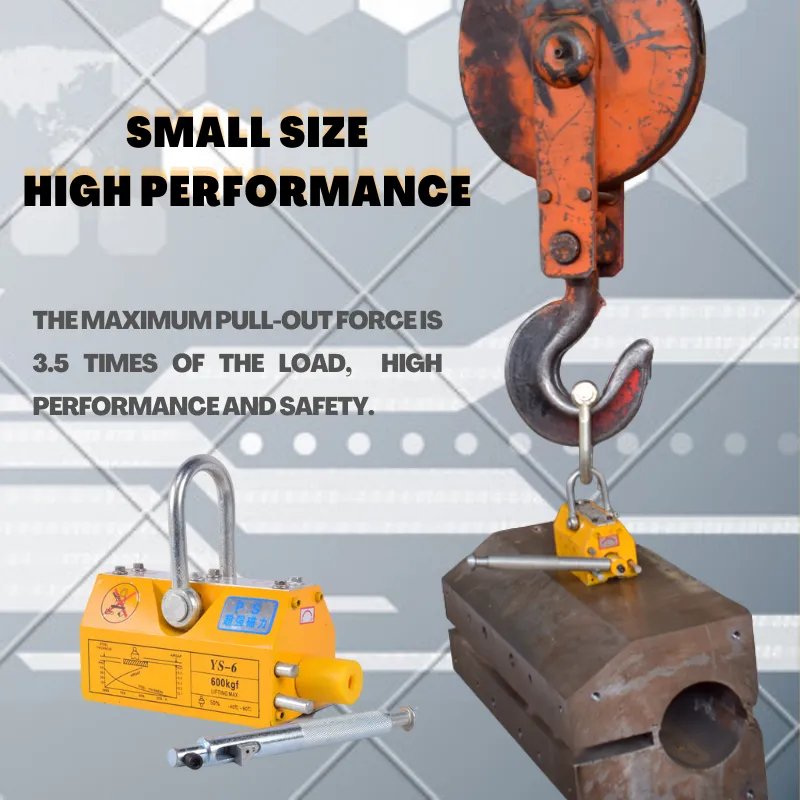

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025