Affordable Rolling Gantry Cranes Available for Purchase with Versatile Applications and High Durability

The Versatility and Efficiency of Rolling Gantry Cranes A Comprehensive Guide

In the world of industrial lifting and material handling, rolling gantry cranes have gained immense popularity due to their versatility, efficiency, and ease of use. Whether you're working in a fabrication shop, a warehouse, or a construction site, a rolling gantry crane can significantly enhance your operations, making it an essential piece of equipment for various tasks.

What is a Rolling Gantry Crane?

A rolling gantry crane is a type of crane that consists of a beam supported by two or more legs that can move on wheels. This design allows the crane to roll along a track or floor, making it an exceptionally flexible lifting solution. Unlike traditional overhead cranes that are fixed in place, rolling gantry cranes can be relocated easily within a work area, adapting to different needs as they arise.

Key Features and Benefits

1. Mobility One of the primary advantages of rolling gantry cranes is mobility. Their wheeled design enables them to be moved effortlessly, allowing operators to position them in the most convenient location for their lifting tasks. This feature is particularly beneficial in large open spaces or areas where multiple workstations are used.

2. Flexibility Rolling gantry cranes come in various sizes and load capacities, catering to different industrial requirements. They can be used for lifting and moving loads ranging from light components to heavy machinery. This adaptability makes them a practical choice for small workshops and larger manufacturing facilities alike.

3. Construction and Setup Setting up a rolling gantry crane is a straightforward process. Many models are designed for easy assembly and disassembly, making them ideal for temporary setups, outdoor projects, or various job sites. This ease of setup encourages businesses to invest in them for a variety of applications.

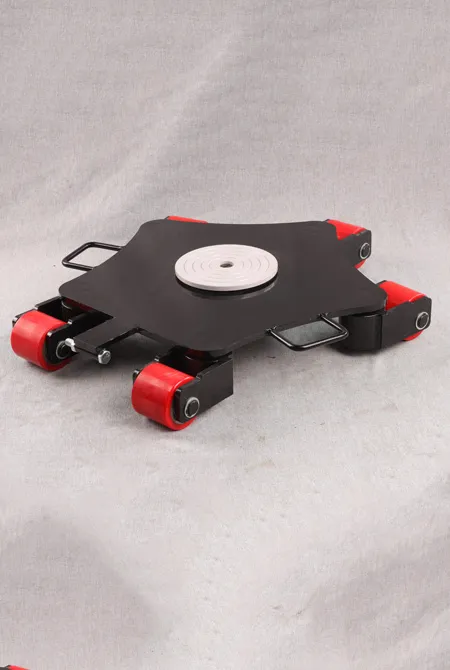

rolling gantry crane for sale

4. Cost-Effectiveness Compared to more extensive lifting systems, rolling gantry cranes are often more affordable. They require less infrastructure and can be used in spaces where larger cranes would not fit. Additionally, their versatility can lead to time savings on projects, ultimately reducing costs.

5. Safety Features Most modern rolling gantry cranes are equipped with safety features such as locking mechanisms, limit switches, and emergency brake systems, ensuring that lifting operations are conducted securely. These features help prevent accidents and protect both workers and materials.

Applications

Rolling gantry cranes are used across various industries. In manufacturing, they assist in assembling large components or moving parts around the shop floor. In construction, they are utilized for lifting heavy materials onto scaffolding and structures. Additionally, they find applications in shipyards, automotive repair, and even in laboratories, showcasing their broad appeal.

Considerations When Purchasing

When considering the purchase of a rolling gantry crane, several factors should be taken into account - Load Capacity Assess the maximum weight you need to lift and choose a crane that meets or exceeds this requirement. - Height and Span Ensure the crane's dimensions fit within your workspace and can reach the necessary height. - Mobility Requirements Determine if you need a crane that can easily roll over specific surfaces or if it will be used primarily in a fixed position. - Material Consider the materials used in construction, as heavier-duty models are often necessary for industrial applications.

Conclusion

In conclusion, rolling gantry cranes offer significant advantages in mobility, flexibility, and cost-effectiveness for various lifting applications. Their ability to adapt to different tasks makes them an invaluable asset in many industries. As you explore options for rolling gantry cranes for sale, keep in mind the specific needs of your operations to make an informed decision that will enhance productivity and efficiency in your workplace.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025