Exploring the Innovations of Gantry Systems in Modern Engineering Design

The Multifaceted Role of Gantry Systems in Modern Industry

In today’s rapidly evolving industrial landscape, the significance of gantry systems cannot be overstated. These robust frameworks, typically designed to support heavy loads and facilitate the movement of materials, have become indispensable across various sectors, including manufacturing, construction, and logistics. This article explores the multifaceted role of gantry systems, delving into their design, applications, and the advantages they bring to modern industries.

Understanding Gantry Systems

At its core, a gantry system consists of a structure that spans an area, supporting equipment or machinery that can move laterally across its frame. Typically made of steel or aluminum, these systems are highly versatile and can be configured for a variety of applications. The mobility of gantries allows for efficient movement of materials, making them both practical and essential in environments where heavy lifting and precise positioning are required.

Applications Across Various Industries

1. Manufacturing Gantries are often seen in manufacturing facilities, where they serve as cranes for lifting heavy components during assembly lines. They allow for precision in moving parts from one station to another, significantly speeding up the production process. Additionally, gantry systems can be integrated with automated machinery, enhancing efficiency while reducing manual labor.

2. Construction In construction sites, gantry cranes are vital for lifting and positioning large building materials such as steel beams, concrete slabs, and prefabricated components. Their ability to traverse over the construction site means fewer disruptions, allowing workers to focus on tasks without the hindrance of heavy lifting equipment on the ground.

3. Logistics and Warehousing The logistics sector relies heavily on gantry systems for loading and unloading cargo. Automated gantry systems are increasingly utilized in warehouses, where they streamline the process of retrieving and storing goods. Their precision and ability to operate in confined spaces make them ideal for modern, high-density storage environments.

4. Shipbuilding In the marine industry, gantries play a critical role in the shipbuilding process. They facilitate the movement of heavy components from shore to vessel, ensuring that large sections of ships can be assembled efficiently. Without gantry systems, the logistics of ship construction would be significantly more complex.

a gantry

Advantages of Gantry Systems

The adoption of gantry systems in industrial applications offers multiple advantages

1. Increased Efficiency By providing a mobile and adjustable lifting solution, gantries help to minimize downtime and maximize productivity. The time saved during material handling can lead to significant improvements in overall operational efficiency.

2. Space Optimization Gantries can be tailored to specific vertical and horizontal dimensions, allowing companies to optimize their workspace. Unlike fixed installations, gantry systems can be moved to different workstations as needed, making them an adaptable solution in dynamic environments.

3. Enhanced Safety Modern gantry systems come equipped with safety features that reduce the risk of injury during material handling. The automation of lifting and moving processes decreases reliance on manual labor, minimizing accidents related to improper lifting techniques.

4. Cost-Effectiveness Investing in a gantry system can be a cost-effective solution for industries that require frequent lifting of heavy materials. With their durability and versatility, these systems often prove to be more economical in the long run than traditional fixed cranes or lifts.

Conclusion

As industries continue to advance and evolve, the role of gantry systems becomes increasingly essential. Their ability to enhance operational efficiency, optimize space, improve safety, and provide cost-effective solutions makes them a valuable asset in today’s industrial environments. Whether in manufacturing, construction, logistics, or shipbuilding, gantry systems are not merely tools; they are key components of a modern, efficient workflow. As technology progresses, we can expect to see further innovations in gantry design, ensuring that they remain at the forefront of industrial advancements for years to come.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

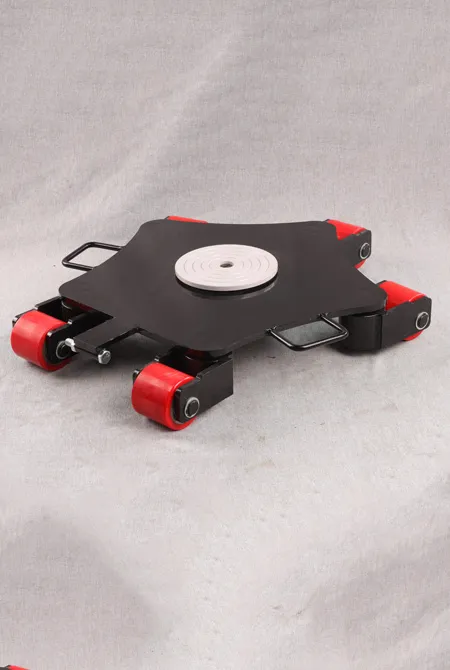

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025