Gantry and Bridge Cranes Key Features and Applications in Heavy Lifting Solutions

Bridge and Gantry Cranes Key Components in Modern Material Handling

Bridge and gantry cranes represent crucial technology in the material handling industry, empowering various sectors, including construction, manufacturing, and shipping. By utilizing the principles of mechanical engineering, these cranes provide effective solutions for moving heavy loads with speed and precision. This article delves into the features, applications, advantages, and considerations associated with bridge and gantry cranes.

Structure and Mechanism

Bridge cranes consist of a horizontal bridge that spans an area, supported by girders or beams. These cranes are mounted on elevated runways, allowing for a wide range of motion both horizontally and vertically. The crane's hoisting mechanism, typically located on the bridge, can raise and lower loads to desired heights. The combination of stability provided by the bridge and the maneuverability of the hoist enables the movement of heavy materials across large workspaces.

Gantry cranes, on the other hand, have a similar structure but are typically freestanding, with their hoisting mechanism located on a framework that stands on legs or supports. This design allows for the clearance of large items or machinery under the crane, making gantry cranes highly versatile for outdoor applications or in environments where space is limited.

Both types of cranes come equipped with a variety of hoisting and lifting mechanisms, including electric, hydraulic, and manual systems, each tailored to specific operational needs.

Applications

The applications of bridge and gantry cranes are vast and diverse. In manufacturing, they are pivotal for the assembly and disassembly of large components, allowing workers to lift heavy parts without risking injury. In construction, these cranes facilitate the transportation of materials to and from various levels of a building under construction, significantly enhancing workflow efficiency.

Shipping yards utilize gantry cranes for loading and unloading cargo containers from ships, showcasing their capability to handle substantial weights

. Similarly, in warehouses and distribution centers, both bridge and gantry cranes streamline the process of moving goods, thereby optimizing space and improving the overall supply chain workflow.bridge and gantry crane

Advantages

One of the significant advantages of bridge and gantry cranes is their ability to lift substantial weights while maintaining stability. This means they can efficiently handle loads that would be impossible or unsafe to move manually. The flexibility of design allows for customization based on specific operational requirements, including the height and span required for lifting operations.

Moreover, the use of automated controls has enhanced operational efficiency. Many modern cranes come equipped with advanced technologies like remote control systems, load sensors, and software for load monitoring, enabling operators to manage cranes safely and effectively from a distance.

Cost-effectiveness is another advantage, as these cranes can significantly reduce the time and labor required for lifting and transporting heavy materials. In industries where time is money, this efficiency translates directly into increased productivity and profitability.

Considerations

While there are numerous benefits associated with bridge and gantry cranes, certain considerations must be kept in mind. Safety is paramount; operators must be adequately trained to handle heavy loads and understand the crane's operational capacities. Regular maintenance is essential to ensure safety and longevity, as wear and tear can lead to malfunctions.

Additionally, the workspace must accommodate the crane's design and operational range. Companies should conduct thorough assessments and planning to ensure the crane's integration into their existing infrastructure does not disrupt workflow or safety protocols.

Conclusion

Bridge and gantry cranes play an indispensable role in modern material handling, revolutionizing how industries manage heavy loads. Their unique designs, vast applications, and ability to enhance efficiency make them a preferred choice in various sectors. As technology continues to advance, the future of bridge and gantry cranes appears promising, with innovations poised to enhance their capabilities further, streamline operations, and reaffirm their importance in the material handling landscape. In an ever-evolving industrial environment, these cranes will undoubtedly remain a cornerstone of heavy lifting and logistics, meeting the demands of modern enterprises.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

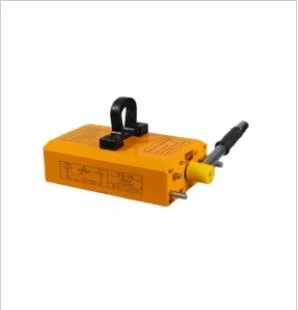

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025