bridge and gantry crane

Understanding Bridge and Gantry Cranes Key Components and Applications

Bridge and gantry cranes are essential pieces of equipment in various industries, facilitating heavy lifting and transporting tasks that would be otherwise impossible using manual labor alone. These cranes are specifically designed to handle substantial loads while ensuring safety and efficiency in operations. This article delves into the mechanics, applications, and advantages of bridge and gantry cranes, highlighting their significance in modern industrial settings.

Structure and Mechanism

At its core, a bridge crane consists of a horizontal bridge structure supported by two or more vertical legs. The bridge runs along rails installed on the walls or ceilings of a building, enabling it to traverse the entire work area. A hoist attached to the bridge allows vertical lifting and lowering of heavy objects. The design can be configured in a variety of ways, including single girder or double girder setups, depending on the weight capacity required and the spatial constraints of the facility.

In contrast, a gantry crane operates on a similar principle but is supported by legs that move on the ground, providing flexibility for outdoor use. Gantry cranes can be either full gantry, where the bridge is supported at both ends, or semigantry, which has one end on the ground and the other on a rail. This structure makes gantry cranes particularly useful in locations with limited overhead space and allows them to be used in ports, construction sites, and manufacturing facilities.

Applications Across Industries

Bridge and gantry cranes are used in various sectors, ranging from manufacturing and shipping to construction and logistics. In manufacturing plants, they play a pivotal role in assembling products, moving materials between different workstations, and lifting heavy machinery. In shipping, gantry cranes are primarily utilized for loading and unloading cargo containers from ships, showcasing their efficiency in handling heavy and bulky loads.

In construction, both types of cranes aid in lifting materials such as steel beams, concrete blocks, and other heavy equipment, significantly speeding up the building process. Their ability to operate in confined spaces or on uneven terrain makes them invaluable in completing projects safely and effectively.

bridge and gantry crane

Advantages of Using Bridge and Gantry Cranes

1. Increased Efficiency The primary advantage of using bridge and gantry cranes is the significant boost in productivity they offer. By automating material handling, these cranes minimize labor costs and reduce the risk of injuries associated with manual lifting.

2. Space Optimization Bridge cranes, in particular, free up floor space as they operate overhead. This vertical utilization allows for more room to maneuver and store goods, vital in crowded industrial environments.

3. Customizability Bridge and gantry cranes can be customized to meet specific needs, including modifications for different load capacities, spans, and heights. This flexibility ensures that businesses can adopt solutions that perfectly align with their operational requirements.

4. Durability and Reliability Constructed with strong materials and designed to handle heavy loads, these cranes are built for longevity. Regular maintenance checks further enhance their reliability, making them a wise investment for any operation needing heavy lifting capabilities.

Conclusion

Bridge and gantry cranes are a cornerstone of industrial operations, offering unmatched lifting capacity and versatility. As industries continue to evolve and demand more efficient handling of heavy loads, the role of these cranes will only become more significant. Investing in modern crane systems can provide businesses with the competitive edge they need in today’s fast-paced market, ensuring safety, efficiency, and productivity.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

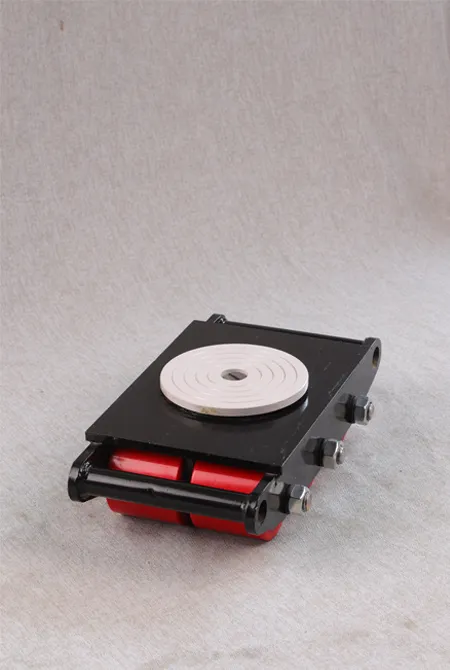

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025