Casters Designed for Easy Movement of Heavy Machinery and Equipment

Casters for Moving Heavy Equipment Enhancing Efficiency and Safety

In various industries, the movement of heavy equipment is an inevitable part of operations. Whether in manufacturing plants, warehouses, or construction sites, efficiently relocating bulky machinery is crucial. The solution lies in the use of casters, an underappreciated yet essential component designed for enhancing mobility and safety when handling heavy loads.

Understanding Casters

Casters are wheeled devices attached to the base of large items, allowing them to be easily moved across floors. They come in various sizes, materials, and designs, each tailored for specific applications. When it comes to moving heavy equipment, choosing the right type of caster can dramatically affect operational efficiency and safety.

Types of Casters

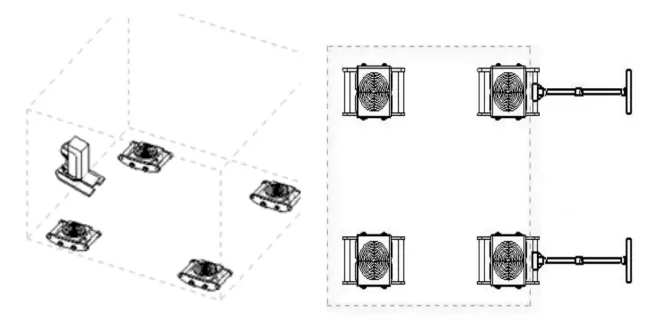

1. Rigid Casters These casters allow for straight-line movement but do not swivel. They are ideal for moving heavy equipment along a predetermined path. Rigid casters provide stability and are commonly used on machines that do not require directional changes during movement.

2. Swivel Casters Swivel casters can rotate 360 degrees, making them suitable for maneuvering equipment in tight spaces. They are ideal for scenarios where adaptability is essential. However, when using swivel casters, it’s important to ensure proper locking mechanisms are in place to prevent unwanted movement.

3. Pneumatic Casters Designed to navigate rough surfaces, pneumatic casters come with inflatable tires that provide cushioning and shock absorption. These are particularly beneficial in construction environments where equipment must traverse uneven terrain.

4. Heavy-Duty Casters When dealing with exceptionally heavy loads, heavy-duty casters are a must. Constructed from robust materials and designed to withstand high pressure, these casters can safely transport industrial machinery weighing thousands of pounds.

Material Considerations

The material of the caster plays a crucial role in its performance. Common materials include rubber, polyurethane, and metal. Rubber casters are ideal for indoor use due to their quiet and smooth operation, while polyurethane options offer superior floor protection and a longer lifespan. Metal casters, typically made from steel, are suited for heavy-duty applications as they can withstand substantial weights and rough conditions.

casters for moving heavy equipment

Load Capacity and Safety

Every caster comes with a specified load capacity, which indicates the maximum weight it can safely support. When selecting casters for heavy equipment, it is vital to consider not only the weight of the equipment itself but also any additional loads that may be applied during movement. Overloading casters can lead to wheel failure, equipment damage, and potential injuries. Generally, it’s advisable to choose casters that exceed the estimated load capacity by at least 20-25% to ensure safety and durability.

Benefits of Using Casters

The benefits of using casters for moving heavy equipment are manifold

1. Increased Efficiency Casters allow workers to move heavy equipment with ease, reducing the time and effort needed for relocation. This increases productivity by minimizing downtime.

2. Enhanced Safety Using casters minimizes the risk of injuries associated with manual lifting or dragging of heavy equipment. They allow for smoother movements and better control, significantly reducing the likelihood of accidents.

3. Protecting Surfaces The right casters can help protect floors from damage. For instance, casters with soft wheels are ideal for preventing scratches and dents on delicate surfaces.

4. Versatility Casters can be easily installed on a wide range of equipment, providing adaptability across various operational needs.

Conclusion

In conclusion, casters are an indispensable asset when it comes to moving heavy equipment. By selecting the appropriate type, material, and load capacity, businesses can enhance their efficiency, protect their staff, and improve overall safety in their work environments. Investing in the right casters not only streamlines operations but also fosters a safer and more productive workspace. Proper consideration in the selection and maintenance of casters will ultimately lead to seamless mobility and operational excellence in any industrial setting.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025