Choosing Casters for Easy Mobility of Heavy Equipment in Various Environments

Choosing the Right Casters for Moving Heavy Equipment

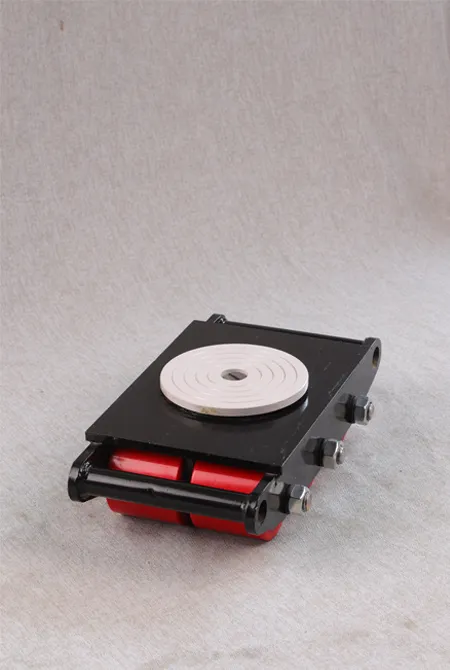

When it comes to moving heavy equipment, selecting the right casters is crucial for ensuring safety, efficiency, and ease of mobility. Casters are the wheels or rollers attached to equipment, carts, or furniture that allow for movement. However, not all casters are created equal; the specific requirements of your heavy equipment dictate which casters will be most effective.

Understanding Load Ratings

One of the first considerations when selecting casters for heavy equipment is load capacity. Each caster has a specified load rating, which indicates the maximum weight it can support. It's essential to calculate the total weight of the equipment, including any additional load it may carry. A good rule of thumb is to choose casters that can support at least 25-30% more than the calculated weight. This precaution ensures that the casters won’t become overloaded, which can lead to malfunction or failure.

Types of Casters

Casters come in various materials and types, each suited for different environments and applications. For heavy equipment, the most common materials are polyurethane, rubber, and steel.

1. Polyurethane Casters These are popular for their durability, shock absorption, and floor protection capabilities. They work well on concrete and other hard surfaces, making them ideal for warehouses and factories where heavy equipment frequently moves.

2. Rubber Casters These casters are best for maneuvering over uneven surfaces or thresholds. Rubber provides excellent traction and minimizes damage to floors, making them suitable for indoor use.

3. Steel Casters For ultra-heavy loads, steel casters offer maximum strength and stability. They are commonly used in industrial settings where heavy machinery is common.

casters for moving heavy equipment

Wheel Size and Swivel vs. Rigid

Another key consideration is the size and type of wheel. Larger wheels roll more easily over obstacles and reduce the effort required to move heavy loads. However, they may take up more space and can be less maneuverable in tight areas.

Casters can also be categorized as swivel or rigid. Swivel casters allow for easier maneuvering, while rigid casters provide straight-line mobility. For optimal performance, a combination of both is often the best solution, with rigid casters used for straight sections and swivel casters for turns and corners.

Brakes and Safety Features

Safety should never be overlooked when moving heavy equipment. Consider casters that come with braking mechanisms. These brakes can lock the wheels in place, preventing any unwanted movement when the equipment is stationary. Some casters also feature shock-absorbing technology, which can reduce the risk of injury and equipment damage during transportation.

Environmental Considerations

Where you plan to use your heavy equipment will also influence your caster choice. For outdoor environments, consider weather-resistant materials that can withstand moisture and UV exposure. In wet or chemical-laden environments, stainless steel casters might be necessary to prevent corrosion.

Conclusion

In summary, choosing the right casters for moving heavy equipment involves careful consideration of load capacity, wheel material, size, and type, as well as safety features. By understanding your specific needs and evaluating the various options available, you can select casters that will not only enhance mobility but also improve the overall efficiency and safety of your operations. Investing in quality casters tailored to your equipment’s requirements can greatly simplify the management of heavy loads and contribute to a smoother workflow.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025