casters for moving heavy equipment

The Importance of Casters for Moving Heavy Equipment

In the world of industry and commerce, the ability to move heavy equipment safely and efficiently is a crucial aspect that impacts productivity and operational efficiency. Among the most essential tools for this purpose are casters, which have evolved over time to become integral components of material handling systems. This article explores the importance of casters for moving heavy equipment, their benefits, and key factors to consider when selecting the right casters for your specific needs.

Understanding Casters

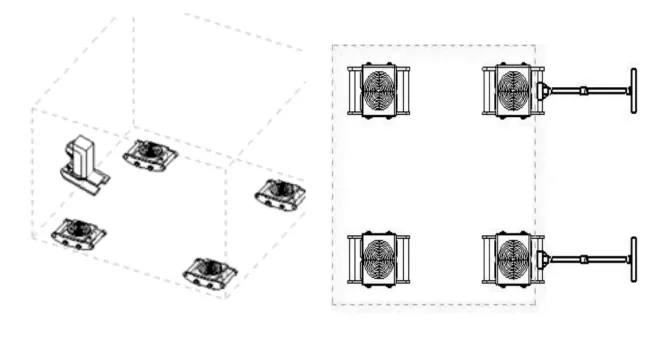

Casters are wheeled devices that can be attached to various types of equipment such as carts, trolleys, and even large machinery. They enable convenient mobility, allowing operators to transport items from one location to another with minimal effort. Casters come in various sizes, materials, and designs, making them suitable for a wide range of applications, particularly in warehouses, factories, and construction sites.

Advantages of Using Casters

1. Ease of Movement One of the primary benefits of using casters is the ease of moving heavy equipment. They significantly reduce the physical strain on workers, enabling them to transport heavy loads with greater efficiency. This ease of movement can lead to increased productivity as less time is spent maneuvering heavy items.

2. Versatility Casters are versatile and can be used in a variety of environments and situations. Whether it’s a small workshop or a large industrial facility, there are casters designed to handle different loads, surfaces, and environmental conditions. This versatility makes them an invaluable tool in various industries, including manufacturing, healthcare, and logistics.

3. Reduced Risk of Injury The manual handling of heavy equipment poses a risk of injury to workers. Casters help mitigate this risk by minimizing the physical effort required to move items. This leads to a safer working environment and reduces the likelihood of accidents and related worker compensation claims.

4. Smooth Operation High-quality casters are designed for smooth movement. They can swivel and rotate easily, allowing for precise maneuverability even in tight spaces. This quality makes it easier to navigate complex shop floors or warehouse aisles without damaging the surroundings or the equipment being transported.

5. Durability and Reliability Many casters are built to withstand substantial weight and harsh working conditions. Heavy-duty casters are made from robust materials such as steel and polyurethane, ensuring they can handle the demands of heavy equipment without breaking down. Choosing reliable casters means fewer replacements and repairs, which can save time and money.

casters for moving heavy equipment

Choosing the Right Casters

When selecting casters for moving heavy equipment, several factors need to be considered to ensure optimal performance

1. Weight Capacity It's essential to choose casters that can handle the weight of the equipment being moved. Each caster has a specified weight capacity, and it's important not to exceed this limit to avoid failures.

2. Surface Type The type of surface on which the casters will be used also influences the choice. Hard surfaces (like concrete) require different caster materials and designs compared to softer surfaces (like carpet). Selecting the right casters for the surface can enhance maneuverability and prevent damage.

3. Wheel Material Different materials offer various benefits. For example, polyurethane wheels provide a smooth roll and are gentle on floors, while rubber wheels offer great shock absorption. Consider the environment and usage when selecting wheel materials.

4. Swiveling vs. Fixed Casters Depending on the required level of maneuverability, you might choose between fixed casters, which only move forward and backward, or swivel casters, which can rotate in any direction. A combination of both can often provide the best results.

5. Brake Mechanisms For added safety, particularly when moving heavy loads, consider casters with effective brake mechanisms. These can prevent equipment from rolling when it’s stationary, ensuring stability during use.

Conclusion

Casters play a pivotal role in enhancing the efficiency and safety of moving heavy equipment across various industries. Their ease of use, versatility, and ability to significantly reduce the risk of injury make them indispensable tools. When choosing casters, considerations such as weight capacity, surface type, and wheel material are crucial in ensuring you select the most appropriate options for your needs. Ultimately, investing in the right casters not only improves productivity but also contributes to the overall safety and effectiveness of your operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025