circular lifting magnets

The Versatility and Efficiency of Circular Lifting Magnets

In the realm of material handling and heavy lifting, circular lifting magnets have emerged as a crucial tool for various industries. These innovative devices utilize electromagnetic principles to lift and transport ferromagnetic materials efficiently and safely. Their design, functionality, and applications make them essential in places such as warehouses, recycling facilities, and manufacturing plants.

The Mechanism of Circular Lifting Magnets

Circular lifting magnets operate on the principle of electromagnetism. When an electric current is passed through the coil of wire wound around a steel core, a magnetic field is generated. This magnetic field can be intensified by using high-quality iron as the core material, which allows the magnet to lift substantial loads. The lifting capacity of these magnets varies, with some models capable of lifting several tons, making them ideal for handling heavy ferrous materials.

One of the primary advantages of circular lifting magnets is their ease of operation. They can be activated and deactivated with a simple switch, allowing operators to quickly lift and release loads without the need for additional equipment such as slings or hooks. This efficiency streamlines the entire lifting process, enhancing productivity in busy industrial environments.

Applications of Circular Lifting Magnets

Circular lifting magnets are utilized in a wide array of applications across different sectors. One of their most common uses is in the steel industry, where they facilitate the handling of steel plates, sheets, and coils. The ability to lift these heavy materials without causing damage is a significant advantage, as traditional lifting methods can sometimes lead to buckling or scratches.

circular lifting magnets

In the recycling industry, circular lifting magnets play a vital role in sorting ferrous metals from the waste stream. They can easily separate iron and steel items from non-ferrous materials, enabling efficient recycling processes. This not only helps in reducing landfill waste but also supports the recovery of valuable materials, thus promoting sustainability.

Moreover, these magnets are prevalent in manufacturing environments where components need to be moved frequently. For instance, they are used in assembly lines for lifting and positioning parts, reducing manual handling and minimizing the risk of injury to workers. The ability to automate these processes using circular lifting magnets contributes to safer and more efficient production lines.

Safety Features and Considerations

While circular lifting magnets offer numerous benefits, safety remains a paramount concern. It is crucial for operators to understand the rated lifting capacity and to ensure that loads do not exceed this limit. Additionally, maintenance checks should be routinely performed to ensure the electrical components and the magnetic core are functioning correctly.

Employers should also train personnel on safe operational practices, which include securing loads appropriately and employing proper lifting techniques. Regular inspections and adherence to safety regulations can significantly reduce the risk of accidents associated with lifting operations.

Conclusion

Circular lifting magnets stand out as a versatile solution for various lifting and material handling tasks. Their effectiveness in lifting heavy ferrous loads, combined with ease of operation and safety features, makes them indispensable in modern industrial applications. As industries continue to advance, the adoption of such technologies is likely to increase, further enhancing operational efficiency and safety. Whether in recycling plants or manufacturing facilities, the role of circular lifting magnets in improving productivity and sustainability cannot be overstated.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

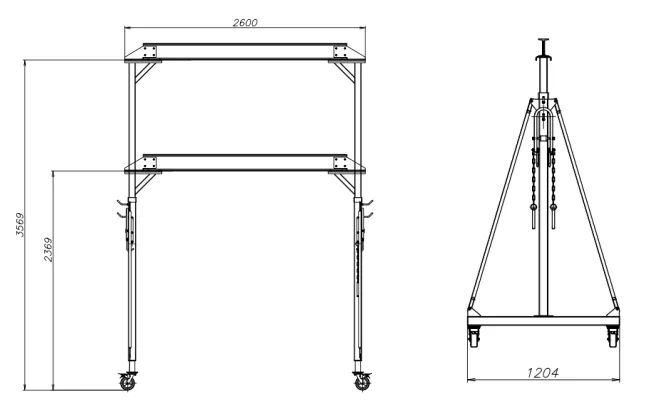

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025