Compact Gantry Crane Solutions for Efficient Material Handling in Limited Spaces and Tight Work Environments

The Advantages and Applications of Small Gantry Cranes

In the realm of material handling and lifting equipment, small gantry cranes have emerged as vital tools for various industries. These devices, characterized by their versatile structure and compact design, offer a range of benefits that cater to both industrial and small-scale applications. As businesses continue to embrace efficiency and safety, small gantry cranes stand out as an indispensable asset in today's fast-paced work environments.

What is a Small Gantry Crane?

A small gantry crane is a type of overhead crane that consists of a horizontal beam supported by vertical legs, which are mounted on wheels or fixed to a surface. This design allows the crane to move items horizontally while providing a significant lifting capacity. Unlike larger cranes that require extensive space and installation, small gantry cranes can be easily assembled and disassembled, making them ideal for temporary or semi-permanent setups.

Key Advantages

1. Portability One of the most significant advantages of small gantry cranes is their portability. Many models are equipped with wheels, allowing them to be moved quickly between work areas. This feature is particularly beneficial in workshops, garages, and warehouses where space is limited but multiple lifting tasks must be performed.

2. Cost-effectiveness Small gantry cranes are generally more affordable than large industrial cranes, making them accessible to businesses of all sizes. Their relatively low cost, combined with their versatility, ensures that companies can invest in reliable lifting solutions without straining their budgets.

3. Ease of Use These cranes are designed for user-friendly operation. Many models can be operated manually, requiring little training for employees to get started. Additionally, they often come with adjustable height options, further enhancing their ease of use and adaptability to different tasks.

small gantry crane

4. Space Efficiency The compact design of small gantry cranes means they require less space than traditional lifting systems. This feature is critical in environments where every square foot counts, ensuring that operations can proceed smoothly without overcrowding.

5. Safety Using a small gantry crane reduces the risks associated with manual lifting and handling. These cranes have built-in safety features, such as limit switches and emergency stops, which contribute to a safer working environment. Moreover, they stabilize loads, minimizing the risk of accidents during equipment operation.

Applications of Small Gantry Cranes

Small gantry cranes are used across various industries due to their versatility. In manufacturing, they assist in moving parts and materials along assembly lines, enhancing workflow efficiency. In construction, these cranes can be used for lifting lightweight materials, tools, and equipment, streamlining project tasks. Additionally, the automotive industry frequently utilizes small gantry cranes for lifting engines and other heavy components during repairs and maintenance.

Beyond industrial applications, small gantry cranes are also beneficial in home workshops, where hobbyists and DIY enthusiasts can use them for lifting heavy materials or machinery safely. Their adaptability makes them suitable for a wide range of tasks, from art installations to equipment maintenance.

Conclusion

In conclusion, small gantry cranes represent a perfect blend of functionality, safety, and efficiency, making them invaluable in modern material handling. Their portability, ease of use, and cost-effectiveness enable businesses and individuals alike to tackle lifting tasks with confidence and safety. As industries continue to evolve, the demand for versatile and effective lifting solutions will only grow, solidifying the role of small gantry cranes as essential tools in a myriad of applications. Whether for industrial use or DIY projects, these cranes help lift the productivity and safety standards of their users.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

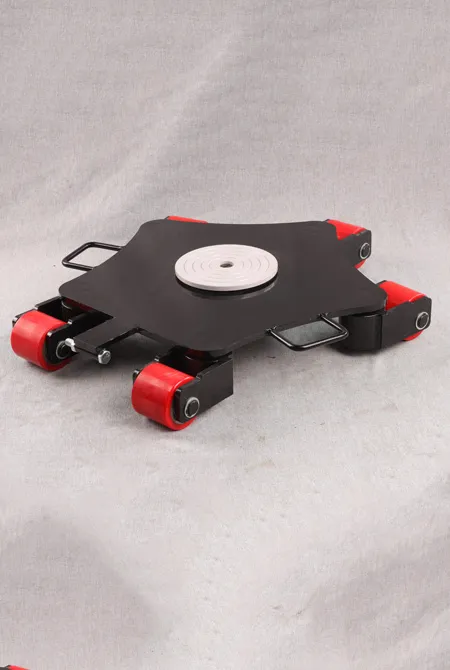

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025