Compact Gantry Crane Solutions for Efficient Material Handling in Limited Spaces and Various Applications

Understanding Mini Gantry Cranes A Comprehensive Overview

In the world of material handling and construction, efficiency and versatility are key factors that determine the success of operations. Among the various equipment available, mini gantry cranes have emerged as a popular choice for many businesses, especially in confined spaces where traditional cranes may not fit. This article explores the features, applications, benefits, and considerations regarding mini gantry cranes.

What is a Mini Gantry Crane?

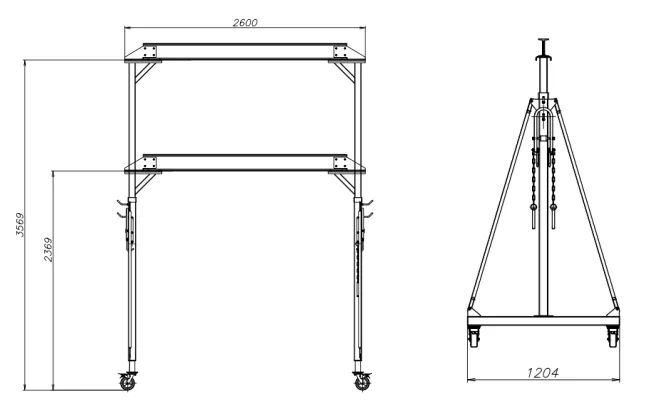

A mini gantry crane is a portable lifting device designed to handle heavy loads in spaces where standard cranes cannot operate effectively. Typically constructed from lightweight materials such as aluminum or steel, these cranes have a simple design that consists of two vertical legs and a horizontal beam, forming a frame that can support a hoist. Available in various sizes and load capacities, mini gantry cranes can easily be transported and set up in different locations, making them ideal for various industries.

Key Features

1. Portability One of the standout features of mini gantry cranes is their lightweight design, which allows them to be easily transported. Many models come with wheels or casters for added mobility.

2. Adjustable Height Many mini gantry cranes come with adjustable height options. This feature is particularly beneficial for projects that require different lift heights, allowing users to customize their setup based on the specific requirements of the task.

3. Load Capacities While termed mini, these cranes can handle a surprisingly wide range of load capacities, commonly ranging from 500 lbs to 2,000 lbs or more, depending on the model. This versatility makes them suitable for various applications.

4. Ease of Assembly Mini gantry cranes are designed for quick assembly and disassembly. Most models require minimal tools to put together, making them user-friendly and time-efficient.

Applications

Mini gantry cranes are employed in a variety of sectors including

- Manufacturing They are often used for lifting and moving heavy components in assembly lines, allowing workers to efficiently manage workload and enhance productivity. - Construction In construction sites with limited space, these cranes facilitate lifting materials such as beams, panels, or tools, improving safety and efficiency.

- Warehouse Operations Mini gantry cranes provide a practical solution for warehouses looking to optimize space while effectively handling goods.

mini gantry crane

- Maintenance and Repair They are also common in maintenance environments for tasks such as lifting engines or heavy machinery for repairs.

Benefits

1. Space Efficiency Their compact size allows mini gantry cranes to function in tight spaces, making them a valuable asset for operations in limited areas.

2. Cost-Effective Compared to full-size gantry cranes, mini models are often more affordable both in terms of purchase price and operational costs.

3. Versatility With adjustable features and various attachments, mini gantry cranes can be tailored to fit an array of tasks, making them suitable for multiple industries.

4. Safety They reduce the risk of manual handling injuries by providing mechanical lifting assistance, thereby promoting a safer working environment.

Considerations

While mini gantry cranes offer numerous advantages, there are factors to consider before purchasing one

- Load Rating It's crucial to select a mini gantry crane with an appropriate load capacity for your specific needs to ensure safety and functionality.

- Installation Space Assess the area where the crane will be used to ensure it fits comfortably without obstruction.

- Maintenance Regular inspection and maintenance are essential to ensure longevity and safe operation, given their mechanical nature.

Conclusion

Mini gantry cranes represent a flexible and efficient solution for various lifting needs. Their portability, ease of use, and adaptability make them a favorable choice across different industries. By understanding the features, benefits, and applications of mini gantry cranes, businesses can enhance their material handling processes and ensure safer, more productive work environments.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025