cost of moving heavy machinery

The Cost of Moving Heavy Machinery An In-Depth Analysis

Moving heavy machinery is an essential aspect of various industries, including construction, manufacturing, and mining. However, this process is not only physically demanding but also incurs significant costs. Understanding the cost components associated with moving heavy machinery is crucial for businesses to optimize their budgets and improve operational efficiency.

1. Transportation Costs

Transportation is perhaps the most apparent cost factor when it comes to moving heavy machinery. The expenses in this category can vary greatly depending on the distance between the current and new locations, the weight and dimensions of the machinery, and the mode of transport used. Companies can choose to transport machinery via road, rail, or water, with each option having its own pricing structure, fees, and logistical challenges.

For instance, flatbed trucks are often used for short-distance moves, whereas specialized trailers may be required for particularly heavy or cumbersome equipment. Additionally, when transporting machinery across state or international borders, businesses might incur extra fees such as customs duties and taxes.

2. Labor Costs

Another significant cost component is labor. Moving heavy machinery typically requires skilled personnel, including operators, riggers, and truck drivers. These specialists ensure that the machinery is handled safely and efficiently, minimizing the risk of damage during relocation. Labor costs can also include overtime wages, especially if the move needs to be expedited or happens outside of regular working hours.

Furthermore, companies must consider the training and certification required for employees to operate heavy machinery safely. Investing in safety training not only complies with regulations but also helps mitigate the potential costs associated with accidents and injuries during the moving process.

cost of moving heavy machinery

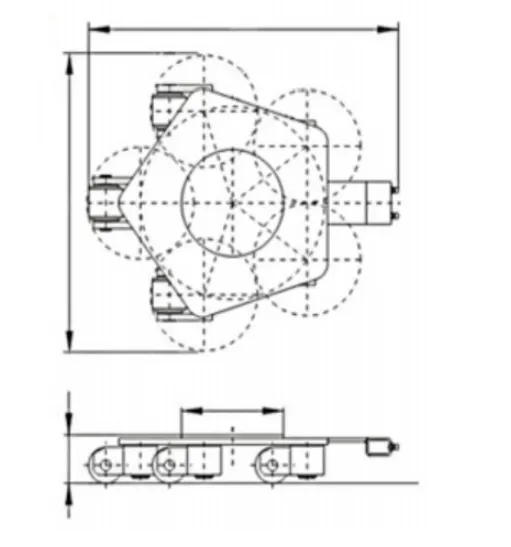

The right equipment is essential for safely moving heavy machinery. This includes lifting devices, cranes, dollies, and straps, which must be adequately maintained and sometimes rented or purchased specifically for a move. The costs related to this equipment can add up quickly, especially if the machinery being moved is particularly large or heavy.

Additionally, companies must factor in potential wear and tear on their existing equipment, which may require maintenance or replacement after extensive use during the relocation process.

4. Insurance and Liability

Insurance is another crucial aspect to consider when calculating the costs of moving heavy machinery. Companies should obtain adequate coverage to protect against potential damages that could occur during the relocation process. This may involve specialized insurance policies tailored to heavy equipment transport. Premiums can vary based on the value and type of machinery being moved, as well as the distance and transport methods used.

5. Downtime Costs

Finally, it is important to recognize that moving heavy machinery may result in downtime for operations. As machinery is being relocated, production may be halted, leading to potential loss of revenue. While this cost is often overlooked, it can significantly impact a company's bottom line. Proper planning and scheduling can help minimize downtime, allowing for a smoother transition.

Conclusion

In conclusion, the cost of moving heavy machinery encompasses various factors, including transportation, labor, equipment, insurance, and potential downtime. Businesses must carefully assess these elements to create an effective budget and streamline their operations. By understanding and managing these costs, companies can ensure that machinery relocation occurs with minimal disruption, ultimately contributing to their long-term success.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025