Calculating Expenses for Relocating Oversized Machinery Efficiently and Affordably

The Cost to Move Heavy Equipment Key Considerations and Strategies

Moving heavy equipment can be a daunting task, both logistically and financially. Industries such as construction, mining, and manufacturing frequently require the relocation of heavy machinery, and understanding the cost attached to such moves is critical for effective project management and budgeting. This article delves into the various factors that influence the cost to move heavy equipment and strategies businesses can employ to manage these expenses effectively.

Factors Influencing the Cost

1. Type of Equipment The cost to move heavy equipment is significantly influenced by the type of machinery being transported. Specialized equipment, such as cranes or excavators, often requires unique handling, which can increase costs. Additionally, larger and more complex machines might necessitate additional permits and safety measures, further enhancing expenses.

2. Distance of Transport Transportation costs generally increase with distance. The longer the distance the equipment must travel, the higher the overall expenses due to fuel costs, labor, and potential tolls or fees associated with long-haul transport. Companies must also factor in the potential downtime of equipment, which can impact project timelines and budgets.

3. Transportation Method The method chosen for moving heavy machinery can significantly affect costs. Standard flatbed trucks may suffice for some equipment, while others may require specialized lowboy trailers or even rail transport for vast distances. Each method comes with its own set of costs, including rental of transport vehicles, insurance, and specialized handling services.

4. Labor Costs Moving heavy equipment is not just about the machinery; it requires skilled labor for loading, securing, transporting, and unloading the equipment. Labor costs can vary widely based on location, experience level of workers, and duration of the project. Proper planning and scheduling can help streamline labor usage and minimize overtime costs.

5. Permits and Regulations Moving heavy equipment often requires compliance with various local, state, and federal regulations. This includes obtaining necessary permits for oversized loads or special transport. The costs associated with these permits can add up quickly and should be factored into the overall budget.

6. Time of Year Seasonal factors can dictate transportation costs. For instance, winter weather can create delays and necessitate additional safety measures, which can increase costs. On the other hand, peak construction seasons may lead to higher demand for transport services, further driving up prices.

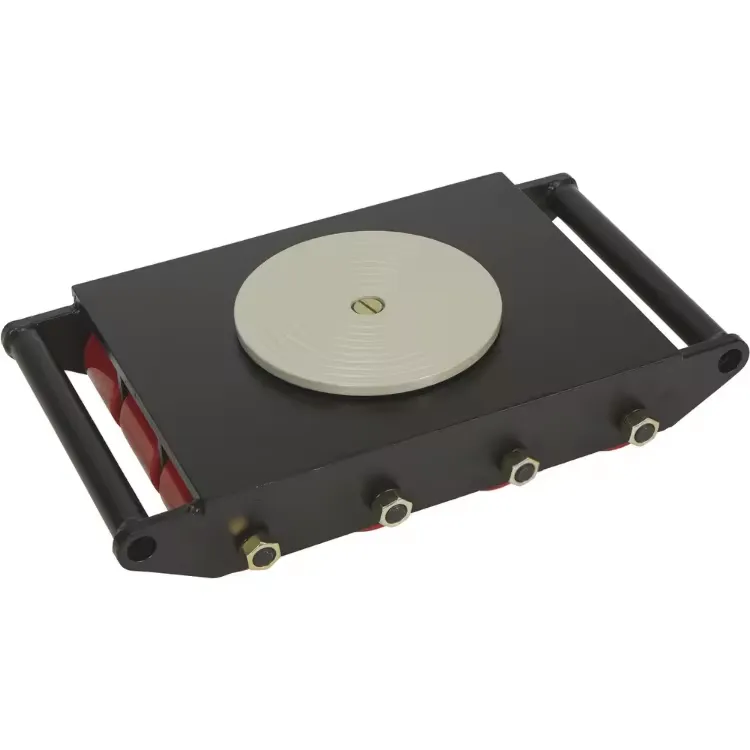

cost to move heavy equipment

Strategies for Cost Management

1. Planning Ahead Effective planning can mitigate costs associated with moving heavy equipment. By scheduling moves during off-peak times and ensuring all permits are secured well in advance, companies can avoid last-minute expenses and delays.

2. Utilizing Technology Leverage technology to optimize routes and schedules. Using GPS and transportation management systems can help identify the most efficient paths, reducing fuel costs and transit times.

3. Negotiating Rates Establishing long-term relationships with transportation providers can yield better rates due to volume discounts. Negotiating contracts can also lead to more favorable terms, potentially reducing overall expenditure.

4. Insurance Considerations Ensure that the equipment is adequately insured during transport. While this may seem like an additional cost, it can save significant amounts in case of damage or loss during the move.

5. Regular Maintenance Keeping heavy equipment in good condition can minimize transport issues. Well-maintained machinery is less likely to face breakdowns, complications, or excessive delays during relocation.

6. Training Workers Investing in training for workers involved in moving heavy machinery can enhance efficiency and safety. Proper training minimizes mistakes and accidents that can lead to additional costs.

Conclusion

The cost to move heavy equipment encompasses a wide array of factors, from transportation methods to regulatory compliance. However, with careful planning and strategic measures, businesses can manage and potentially reduce these costs. By investing in proper logistics, leveraging technology, and fostering good relationships with transport providers, companies can ensure that their heavy equipment moves are as efficient and cost-effective as possible. Whether for a single move or ongoing operations, understanding these dynamics is key to maintaining profitability in industries reliant on heavy machinery.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025