crane gantry girder

Understanding Crane Gantry Girders An Overview

Crane gantry girders are integral components in the design and functionality of various lifting mechanisms used in industrial environments. These systems are primarily designed to support cranes that operate in manufacturing units, shipping yards, and construction sites, where heavy materials need to be transported efficiently and safely.

A gantry crane is characterized by its unique structure, which consists of a horizontal bridge supported by two or more vertical posts. The girder is the key horizontal component that extends across the span of the crane, allowing for the movement of the hoisting mechanism. The design and material of the gantry girder play a significant role in determining the crane's load capacity, stability, and overall efficiency.

Typically, gantry girders can be constructed from a variety of materials, including steel or aluminum, depending on specific operational requirements. Steel is the most commonly used material due to its high tensile strength, ease of fabrication, and cost-effectiveness. Aluminum, while lighter and resistant to corrosion, is often used for applications requiring lower load capacities.

The design of a crane gantry girder involves several engineering factors, including load calculations, material selection, and structural integrity

. Engineers must consider the weight of the items to be lifted, the maximum span required, and the environmental conditions where the crane will operate. This meticulous planning ensures that the gantry girder can support substantial loads while maintaining safety standards.crane gantry girder

One of the primary advantages of using a gantry crane with a robust gantry girder is its versatility. These cranes can be used in outdoor and indoor settings and can easily be customized to fit specific operational requirements. Adjustable legs or height settings can be integrated into the design to allow the crane to accommodate various tasks.

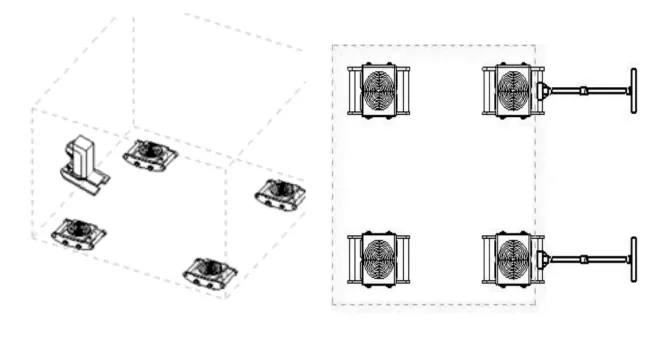

Moreover, gantry cranes are known for their mobility. Many designs incorporate wheels or tracks, enabling the crane to be moved along a predetermined path for optimal efficiency in material handling. This characteristic is particularly beneficial in situations where the workspace is constrained or when versatility is a priority.

Safety is another critical aspect associated with crane gantry girders. The design must incorporate features that prevent overloading, such as load monitoring systems and emergency stop mechanisms. Regular maintenance and inspections are also vital to ensure that the gantry girder and associated components remain in peak condition, preventing accidents and ensuring the safety of operators.

In summary, crane gantry girders play a pivotal role in enhancing the efficiency and safety of material handling operations across various industries. Their robust design, adaptability, and mobility make them invaluable tools in modern industrial applications. As technology continues to evolve, we can anticipate further advancements in the design and functionality of gantry girders, ensuring they meet the ever-growing demands of the industrial landscape. By understanding the significance of these components, businesses can make informed decisions in selecting the right equipment to enhance productivity and safety in their operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025