Comparison of Crane Girders and Gantry Girders in Structural Applications

Crane Girders and Gantry Girders An Overview

In the realm of construction and engineering, the understanding of load-bearing structures is paramount to ensuring the safety, efficiency, and reliability of heavy lifting operations. Among these structures, crane girders and gantry girders stand out as essential components in various industrial applications. This article delves into the definitions, types, applications, and considerations involved in the use of crane girders and gantry girders.

Definitions and Functions

At its core, a crane girder is a structural element that supports the trolley or hoist mechanism of a crane. It is typically installed horizontally and designed to handle varying loads, transferring these loads to vertical supports or columns. Crane girders can be classified into several types, including single girders and double girders, depending on the design requirements and load specifications.

On the other hand, a gantry girder is a framework that provides support for a movable crane structure. It is often utilized in settings where the crane needs to traverse across a larger area, such as in shipping yards, large warehouses, or construction sites. Gantry girders can either be fixed or movable, allowing for flexibility in operations.

Types of Crane Girders

1. Single Girder Crane This type incorporates one main girder that runs the length of the span, typically used in lighter applications. Single girder cranes are easier to install, require less material, and offer cost-effective solutions for low-capacity lifts.

2. Double Girder Crane This design features two parallel girders that provide enhanced strength and stability for heavier operations. As a result, double girder cranes can accommodate larger hoisting capacities and longer spans, making them suitable for industrial settings where heavy machinery is involved.

3. Box Girder Crane This type is distinguished by a box-shaped girder that enhances torsional rigidity and minimizes weight. Box girder cranes are often preferred in environments with limited headroom or stringent space constraints.

Applications of Gantry Girders

Gantry girders are fundamental in various sectors, particularly in

crane girder and gantry girder

1. Shipping and Logistics In shipping yards, gantry cranes equipped with gantry girders facilitate the loading and unloading of containers onto ships. Their ability to navigate across rail tracks or dock areas makes them invaluable for efficient operations.

2. Construction Sites Gantry girders support cranes that raise heavy construction materials to elevated positions, contributing to the efficient progress of building projects.

3. Manufacturing Facilities In factories, gantry systems are common for moving materials along production lines. These systems optimize workflow and enhance productivity.

Considerations in Design and Material Selection

When designing crane and gantry girders, several factors are crucial to ensure structural integrity and performance

1. Load Capacity Understanding the anticipated load is essential for selecting appropriate materials and designs. This involves considering both the static and dynamic loads, including potential shock loads during operations.

2. Material Choices Common materials include steel, which provides high strength-to-weight ratios, and reinforced concrete, which may be more suitable for static installations. The choice of material significantly influences the girder’s durability and maintenance needs.

3. Environmental Conditions Factors such as exposure to corrosive environments, extreme temperatures, or moisture levels can affect material performance. Proper coatings and protective treatments may be necessary to extend the lifespan of girders.

4. Compliance with Standards Adhering to industry standards and regulations is crucial in the design and construction of crane and gantry girders. This ensures safety for operators and stability for the loads being handled.

Conclusion

Crane girders and gantry girders play a pivotal role in the efficient operation of various industries where heavy lifting and transportation are integral to productivity. Understanding their functions, types, applications, and critical design considerations can help engineers and construction professionals make informed choices that enhance safety, efficiency, and longevity in their operations. With the continuous evolution of technology and materials, the future of crane and gantry girders is promising, with innovations likely to improve their effectiveness and adaptability to changing industrial needs.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

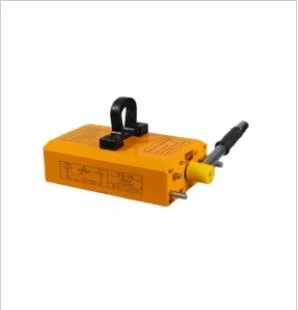

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025