Jan . 15, 2025 04:14

Back to list

Dawei Adjustable Gantry Crane, 2000-Lb. Capacity, 2293mm–3493mm Lift.

Cranes and gantry girders are essential in numerous industrial scenarios, streamlining the handling of heavy loads and increasing efficiency on work sites. To navigate their applications effectively, it's crucial to dive deep into the intricacies of these components, leveraging both real-world experience and authoritative knowledge.

Industry expertise is invaluable when selecting or upgrading these components. Collaborating with a knowledgeable partner ensures that the girders are not only appropriately rated for the intended loads but also compatible with existing systems. Furthermore, routine inspections and maintenance schedules can extend their lifespan significantly, preventing costly downtime. To establish authoritativeness in this domain, it's essential to reference case studies and peer-reviewed research that underline the advancements in materials and technology impacting crane and gantry girder performance. Insights from these studies often uncover innovative practices or emerging trends, such as the use of automated inspection drones or sensor-embedded girders for real-time stress monitoring. Trustworthiness is built through transparency and adherence to international standards. Adopting practices that comply with ISO and OSHA guidelines demonstrates a commitment to quality and safety that resonates with clients seeking dependable solutions. Clear communication during all phases—design, installation, and maintenance—fosters a culture of trust, aligning client expectations with deliverable performance metrics. In conclusion, the universe of crane girders and gantry girders is expansive, yet the fundamentals remain grounded in a blend of technical expertise, authoritative insights, and unwavering trustworthiness. Emphasizing these pillars not only enhances SEO rankings through quality content but more importantly, guides industry professionals and businesses toward making informed decisions that drive safety, efficiency, and innovation within their operational frameworks.

Industry expertise is invaluable when selecting or upgrading these components. Collaborating with a knowledgeable partner ensures that the girders are not only appropriately rated for the intended loads but also compatible with existing systems. Furthermore, routine inspections and maintenance schedules can extend their lifespan significantly, preventing costly downtime. To establish authoritativeness in this domain, it's essential to reference case studies and peer-reviewed research that underline the advancements in materials and technology impacting crane and gantry girder performance. Insights from these studies often uncover innovative practices or emerging trends, such as the use of automated inspection drones or sensor-embedded girders for real-time stress monitoring. Trustworthiness is built through transparency and adherence to international standards. Adopting practices that comply with ISO and OSHA guidelines demonstrates a commitment to quality and safety that resonates with clients seeking dependable solutions. Clear communication during all phases—design, installation, and maintenance—fosters a culture of trust, aligning client expectations with deliverable performance metrics. In conclusion, the universe of crane girders and gantry girders is expansive, yet the fundamentals remain grounded in a blend of technical expertise, authoritative insights, and unwavering trustworthiness. Emphasizing these pillars not only enhances SEO rankings through quality content but more importantly, guides industry professionals and businesses toward making informed decisions that drive safety, efficiency, and innovation within their operational frameworks.

Next:

Latest news

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

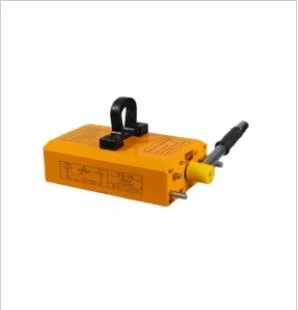

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025