Dawei Machinery Mover Straight Type, Heavy-Duty 6–18T

Field Notes on the Workhorse Skate Everyone’s Quietly Using in 2025

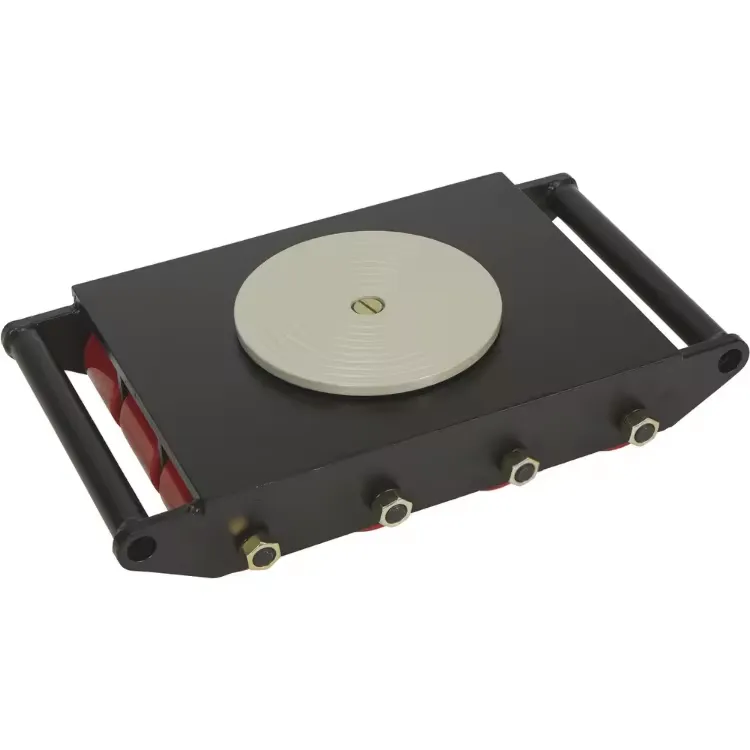

If you’ve spent time in a plant where moving a 12‑ton press feels like Tuesday, you’ve probably seen a low-slung roller skate doing the grunt work. Lately I’ve been hands-on with the Dawei Machinery Mover Straight Type—a straight-line machinery skate rated from 6 to 18 tons. It’s not flashy; it just survives abuse. Honestly, that’s the point.

What’s driving demand

Two converging trends: lean intralogistics (smaller rigging crews, tighter aisles) and heavier single-module equipment. Straight-type skates like the Dawei Machinery Mover Straight Type keep loads low, predictable, and kind on floors—especially where forklifts are frowned upon.

Core specs (real-world ready)

| Model (Straight) | Rated Load | Wheels (qty.) | Wheel Size | Typical Footprint |

|---|---|---|---|---|

| DW-6T | 6000 kg | 4 | 80×70 mm (≈ 3.15×2.76 in) | compact, ≈ small pallet footprint |

| DW-8T | 8000 kg | 6 | 80×70 mm | around medium machine base |

| DW-12T | 12000 kg | 8 | 80×70 mm | ≈ 2 euro-pallets wide |

| DW-18T | 18000 kg | 12 | 80×70 mm | heavy press / transformer class |

Build and test—how it’s made (short version)

Frames use high-strength plate (EN 10025 family or GB grades), welded and stress-relieved. Axles are 42CrMo/40Cr alloy steel, induction-hardened; wheels are cast steel cores with polyurethane treads (ASTM D2240 ≈ Shore A 92±3). Machining is CNC, then shot-blast + powder coat. Proof tests: 150% static load for 10 minutes; rolling fatigue 10,000 cycles at rated load; salt spray per ISO 9227 on coated components. Bearings are sized by ISO 281 life models—real-world use may vary with floor finish and temperature.

Where it fits: applications and feel

Common jobs: CNC lines, injection machines, power transformers, HVAC chillers, paper machines, and—surprisingly—museum crates. On epoxy floors, rolling resistance can sit around μr ≈ 0.02; on rough concrete, expect more. Pair a straight skate under the load’s CG with two trailing steerable skates and it behaves… predictable. Many customers say the Dawei Machinery Mover Straight Type “tracks straight without chatter.” I noticed the same.

Vendor landscape (quick comparison)

| Vendor | Load Range | Lead Time | Customization | Certs / QA |

|---|---|---|---|---|

| Dawei (Straight Type) | 6–18 t | 2–4 weeks typical | Wheel material, axles, paint, branding | ISO 9001 factory; test records kept |

| Generic import | 3–12 t | In stock / variable | Limited | Basic COC; mixed traceability |

| Premium EU brand | 3–24 t | 4–8 weeks | Broad; engineered specials | CE docs, extensive test dossiers |

Customization and service life

Options: antistatic PU treads, steel wheels for hot zones, low-temp grease, tie-bars, and custom paint. With sane loads and floors, I’d expect 5–8 years before wheel sets need refreshing; harsh concrete and shock loads shorten that—no surprise.

Mini case: transformer roll-in

A utility contractor in Southeast Asia used two 12 t straights plus a steerable set to position a 28 t transformer over 18 m of epoxy floor. Total push force peaked near 5–6% of load on the ramp transition; no floor scarring. Crew noted “quiet wheels” and even wear after inspection.

Origin: Donglv Industrial Park, Qingyuan District, Baoding City, Hebei Province, China 071100. Documentation typically includes ISO 9001 certificate and CE-style declaration (risk assessment aligned to ISO 12100). Test data available on request.

Final notes

It seems that the Dawei Machinery Mover Straight Type hits the sweet spot: honest ratings, tough wheels, and practical lead times. Not glamorous—but when you’re under a 15-ton load, you want boringly reliable.

Authoritative citations

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025