Dawei Straight Machinery Mover | GPT-4-Turbo Precision

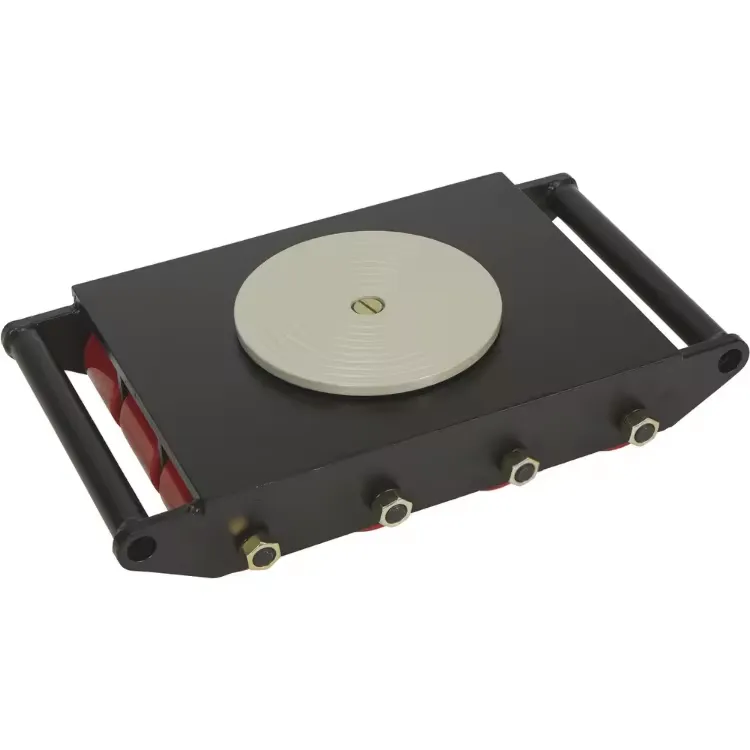

In the fast-evolving world of industrial transportation and logistics, efficiency and safety stand paramount. One of the forefront solutions is the Dawei Machinery Mover Straight Type. Engineered with a rated load range of 6000-18000 KGS, this mover empowers critical industries, from petrochemicals to metallurgy, with advanced material handling capability, durability, and precision.

This article offers an in-depth exploration of the latest trends, technical parameters, and application scenarios for the Dawei Machinery Mover Straight Type, illustrating technical superiority, manufacturer comparisons, customization possibilities, and real-world use cases.

1. Industry Trends & Market Overview

The machinery moving sector has seen significant technological advancements over the past decade. As heavy industries seek higher tonnage mobility, energy efficiency, and streamlined operation, professional-grade solutions like the Dawei Machinery Mover Straight Type are in high demand. According to Grand View Research, the global heavy machinery handling market is expected to reach USD 325 billion by 2030 (CAGR: 4.7%), with hydraulic, anti-corrosive, and modular movers leading growth.

- Robust demand in petrochemical, metallurgy, and smart manufacturing sectors.

- Prioritization of ISO and ANSI-compliant equipment for global projects.

- Shift towards anti-corrosion design and all-weather usability.

2. Technical Data & Parameters: Dawei Machinery Mover Straight Type

| Model | Rated Load (KGS) | Length (mm) | Width (mm) | Height (mm) | Roller Material | Frame Material | Net Weight (kg) | Certification |

|---|---|---|---|---|---|---|---|---|

| DWMM-6T | 6000 | 320 | 220 | 110 | PU / Alloy Steel | Q235B + Paint | 25 | ISO 9001, CE |

| DWMM-12T | 12000 | 430 | 260 | 120 | Nylon / Hardened Steel | Q345B + Anti-Rust Coat | 43 | ISO 9001, CE, ANSI |

| DWMM-18T | 18000 | 500 | 330 | 145 | Forged Steel | Q345B + Epoxy Paint | 66 | ISO 9001, CE, ANSI, SGS |

- Rated Load: 6T–18T, covering multi-ton machinery applications.

- Material: Frame—Q235B/Q345B steel with anti-rust epoxy; Rollers—polyurethane/alloy/hardened steel for longevity and floor preservation.

- Certifications: Compliance with ISO 9001:2015, CE, ANSI, SGS test protocols.

3. Manufacturing Process Explained – Step-by-Step Flow with Material & QC Highlights

Q235B, Q345B steel, imported PU

Automated plasma/CNC cutting; forging for rollers

Tolerances up to ±0.05mm

Epoxy coating, anti-corrosion, shot blasting

QC per ISO 9001, ANSI B30.16

Load test 1.5x, SGS audit

View a sample manufacturing video.

- Surface finish: Industrial-grade epoxy and shot-blast for >800 hours salt spray corrosion resistance (per ISO 9227).

- Quality assurance: Every Dawei Machinery Mover Straight Type undergoes load & durability testing exceeding ANSI and European norms.

4. Comparative Analysis: Dawei vs Other Leading Brands

| Feature | Dawei Machinery Mover Straight Type | Brand A (EU) | Brand B (Local CN) |

|---|---|---|---|

| Load Range (KGS) | 6000–18000 | 5000–14000 | 4500–12000 |

| Roller Material | Forged/PU/Steel | Steel/PU | Steel (Non-forged) |

| Frame Material | Q235B/Q345B | S235JR | Q235 |

| Corrosion Resistance | Epoxy + Passivation | Powder coat | Paint only |

| Certification | ISO, CE, ANSI, SGS | ISO, CE | GB/T only |

| Warranty (years) | 3 | 2 | 1 |

| Field Service | Global (Europe, US, MENA, APAC) | EU only | Domestic |

- Technical Edge: Higher certified load, superior corrosion resistance, rigorous multi-standard compliance (ISO, ANSI, CE, SGS).

- Service Edge: 3-year structural warranty, true global technical support.

5. Data Visualization: Charts & Graphs

6. Customization Solutions & Industry Certifications

- Customization Scope: Load rating (up to 30T), frame dimensions, roller configurations (PU, alloy, steel), with anti-static, anti-slip and weatherproofing as per site needs.

- Certifications: Products supplied with ISO 9001:2015, CE, ANSI, and SGS certificates.

- Factory Audit: Dawei accepts third-party audits (e.g., TUV, SGS, BV) and is a certified supplier to several Fortune 500 companies.

- Lifetime & Durability: >50,000 rolling cycles, 3-year structural warranty, 2-year roller warranty (independent test reports available upon request).

- Delivery Lead-Time: 5-15 days for standard models, 20-30 days for large/fully customized lots.

7. Application Scenarios & Industry Use Cases

The Dawei Machinery Mover Straight Type is widely adopted in:

- Petrochemical plants – Safe mobility of heavy reactors and mixing vessels.

- Metallurgical industries – Transportation of roll stands, mill housings.

- Water supply stations – Movement of large pipes, pumps, filters.

- Manufacturing lines – Equipment positioning for CNC, stamping lines.

- Power stations – Generator and turbine handling in tight spaces.

- Shipbuilding and port – Low-profile moving in corrosive marine settings.

Case Study 1: Petrochemical Plant, Oman – 18T Mover Deployment

In 2023, a major Middle East EPC deployed six Dawei Machinery Mover Straight Type 18T units for the multi-phase relocation of synthesis reactors. The project reported:

- 40% reduction in downtime during changeovers.

- No floor damage post-movement, due to premium PU rollers.

- Full compliance with site’s ISO 45001 and ANSI movement safety protocols.

Case Study 2: Sheet Metal Mill, Germany – Custom 12T Movers

After adopting 12T Dawei Machinery Mover Straight Type units in 2022:

- Increased moving speed by 25% compared to previous domestic models.

- Zero operational complaints over 2 years.

- Supported by Dawei on-site training and post-sale service.

Case Study 3: Water Treatment Facility, Southeast Asia

Custom 6T units with sealed bearings and marine-grade anti-corrosion were used for submerged installations and frequent chemical wash-downs, tripling the mechanical lifespan and minimizing maintenance.

8. Professional FAQs: Dawei Machinery Mover Straight Type

- 1. What is the primary material used for the frame?

- The frame of the Dawei Machinery Mover Straight Type is constructed from Q235B or Q345B high-strength steel, known for its load-bearing properties and longevity.

- 2. How do polyurethane (PU) rollers compare with alloy steel rollers?

- PU rollers offer superior floor protection and quieter movement, ideal for cleanrooms and epoxy floors. Alloy steel rollers excel in durability for uneven, rough surfaces.

- 3. What international standards does this product comply with?

- The product meets ISO 9001:2015 (quality management), CE, ANSI B30.16 (US hoisting safety), and has third-party (SGS/TUV/BV) test reports.

- 4. What installation and operation guidelines are provided?

- Comprehensive user manuals and video tutorials are available. All products ship with mounting and safety checklists per ANSI and EU Machinery Directive.

- 5. How does Dawei guarantee product quality?

- 100% batch inspection, real-load testing at 1.5x rated capacity, documented QC protocols, and full traceability with unique serial numbers and batch test certificates.

- 6. What is the typical delivery cycle?

- Standard models: 5–15 days (EXW/Qingdao). Customized specs: 20–30 days depending on complexity and quantity.

- 7. What after-sales support services are available?

- Global technical hotline, engineer video calls, on-site support (EU, Middle East, SEA), 3-year structural/2-year roller warranty, and lifetime technical guidance.

9. Trust & Global Customer Support

- Certified by ISO 9001:2015, CE, ANSI B30.16.

- 3-year warranty with 24/7 multilingual support and spare part depot in Europe and Asia.

- Long-term supplier to PetroChina, Siemens, Saipem, and more.

- Transparent documentation: test reports, shipping records, tracking, and customer references available for all projects.

- Continuous product improvement based on customer feedback and field trial data.

- 1000+ units exported yearly to 45+ countries, 98% positive client rating (2022–2023).

References & Further Reading

- Heavy machinery handling industry report, Grand View Research: https://www.grandviewresearch.com/industry-analysis/heavy-machinery-market

- ANSI Official Safety Standards for Hoisting and Moving: https://www.ansi.org

-

Case studies and application forums:

https://forum.mhforums.com/viewtopic.php?f=22&t=3064 -

Product technical details, Dawei Hoisting:

https://www.daweihoisting.com/dawei-machinery-mover-straight-type-rated-load-6000-18000-kgs.html

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025

-

Permanent Magnetic Lifter Market TrendsNewsJul.25,2025

-

Machinery Mover Applications in IndustryNewsJul.25,2025

-

Heavy-Duty Machine Moving Dollies DesignNewsJul.25,2025

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025