Jan . 11, 2025 12:01

Back to list

Dawei Adjustable Gantry Crane, 2000-Lb. Capacity, 2293mm–3493mm Lift.

Steel gantry cranes are a pivotal component in various industrial and construction settings, providing robust and reliable lifting solutions. Their unique structure, combining strength with mobility, makes them indispensable for tasks ranging from heavy-duty material handling to delicate transportation of fragile goods.

From a safety perspective, steel gantry cranes are designed with rigorous compliance to industry standards. These standards ensure that each unit undergoes comprehensive testing and quality assurance checks before deployment. As a result, these cranes are equipped with enhanced safety features such as emergency braking systems and overload protection, solidifying their reputation as reliable and safe solutions. The authoritativeness of steel gantry cranes in the market is further validated by their widespread use across various sectors, including manufacturing, shipping, and logistics. Their prominent presence in these industries is not just a function of their mechanical capabilities but also a demonstration of their economic viability. By improving operational workflows, reducing labor costs, and minimizing downtime, steel gantry cranes offer a compelling return on investment. Trustworthiness, especially in a product as critical as lifting equipment, cannot be overstated. Manufacturers of steel gantry cranes build their reputation on delivering products that consistently meet client expectations and withstand rigorous operational demands. This reputation is a key factor when industries evaluate new equipment acquisitions. In conclusion, steel gantry cranes are the epitome of engineering prowess and practical utility, offering unmatched performance in heavy lifting environments. Their construction, grounded in durability and adaptability, renders them a preferred choice across industries worldwide. As such, their continued evolution is poised to meet the ever-changing demands of industrial operations, reaffirming their position as indispensable tools in modern material handling.

From a safety perspective, steel gantry cranes are designed with rigorous compliance to industry standards. These standards ensure that each unit undergoes comprehensive testing and quality assurance checks before deployment. As a result, these cranes are equipped with enhanced safety features such as emergency braking systems and overload protection, solidifying their reputation as reliable and safe solutions. The authoritativeness of steel gantry cranes in the market is further validated by their widespread use across various sectors, including manufacturing, shipping, and logistics. Their prominent presence in these industries is not just a function of their mechanical capabilities but also a demonstration of their economic viability. By improving operational workflows, reducing labor costs, and minimizing downtime, steel gantry cranes offer a compelling return on investment. Trustworthiness, especially in a product as critical as lifting equipment, cannot be overstated. Manufacturers of steel gantry cranes build their reputation on delivering products that consistently meet client expectations and withstand rigorous operational demands. This reputation is a key factor when industries evaluate new equipment acquisitions. In conclusion, steel gantry cranes are the epitome of engineering prowess and practical utility, offering unmatched performance in heavy lifting environments. Their construction, grounded in durability and adaptability, renders them a preferred choice across industries worldwide. As such, their continued evolution is poised to meet the ever-changing demands of industrial operations, reaffirming their position as indispensable tools in modern material handling.

Latest news

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

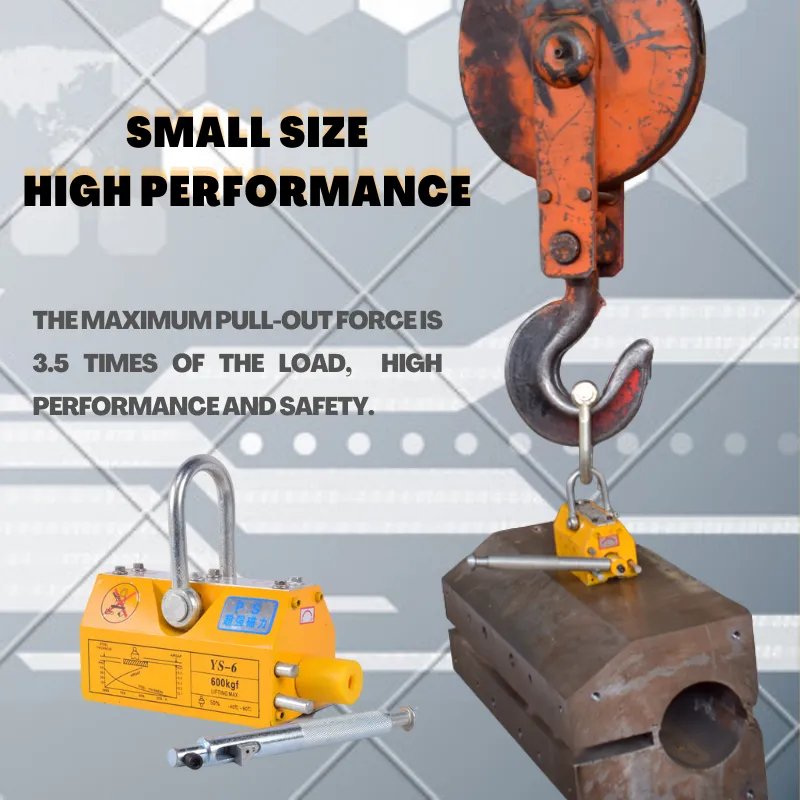

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025