Jan . 13, 2025 16:06

Back to list

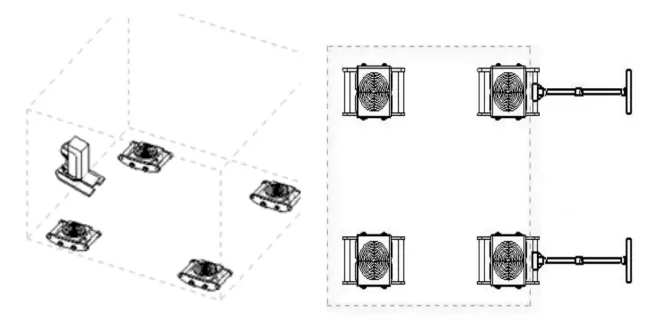

Dawei Adjustable Gantry Crane, 2000-Lb. Capacity, 2293mm–3493mm Lift.

In the world of modern construction and manufacturing, the demand for efficient and versatile material handling solutions has skyrocketed, establishing lightweight gantry cranes as indispensable assets across various industries. With over a decade of experience in optimizing material handling systems, it’s evident how these cranes exemplify a blend of flexibility, innovation, and reliability, crucial for enhancing operational efficiency.

From an authoritative standpoint, investing in a high-quality lightweight gantry crane requires understanding the intricacies of load dynamics and structural integrity. Professionals emphasize the importance of adhering to regional safety standards and conducting regular maintenance checks to ensure prolonged service life. This vigilance not only guarantees safety but also reinforces the crane’s operational reliability, establishing trust with stakeholders and ensuring compliance with industry regulations. Trustworthiness in the utility of lightweight gantry cranes is further solidified through advancements in design and technology. Incorporations such as ergonomic controls, advanced telemetry for load monitoring, and enhanced safety features like lockable casters and stabilizing outriggers underscore the commitment to safe operations. These enhancements are testament to the evolving engineering practices aimed at meeting the stringent demands of modern industries while ensuring operator safety. Moreover, the sustainability factor plays a significant role in their appeal. Engineers and industrial planners prioritize solutions that minimize environmental impact without compromising on performance. Lightweight gantry cranes fit this narrative perfectly, often utilizing recyclable materials and supporting innovative power solutions such as rechargeable battery-driven hoists, thereby reducing their carbon footprint. In conclusion, for any industry professional keen on optimizing their material handling processes, lightweight gantry cranes represent a strategic investment. They combine expert engineering with practical functionality, ensuring that businesses remain at the forefront of operational efficiency. By prioritizing attributes such as portability, reliability, and sustainability, these cranes not only meet but exceed the intricate demands of today's dynamic industrial landscape. Experts continuously advocate for their adoption, reflecting a seamless integration of trusted technology and strategic innovation tailored for future-ready operations.

From an authoritative standpoint, investing in a high-quality lightweight gantry crane requires understanding the intricacies of load dynamics and structural integrity. Professionals emphasize the importance of adhering to regional safety standards and conducting regular maintenance checks to ensure prolonged service life. This vigilance not only guarantees safety but also reinforces the crane’s operational reliability, establishing trust with stakeholders and ensuring compliance with industry regulations. Trustworthiness in the utility of lightweight gantry cranes is further solidified through advancements in design and technology. Incorporations such as ergonomic controls, advanced telemetry for load monitoring, and enhanced safety features like lockable casters and stabilizing outriggers underscore the commitment to safe operations. These enhancements are testament to the evolving engineering practices aimed at meeting the stringent demands of modern industries while ensuring operator safety. Moreover, the sustainability factor plays a significant role in their appeal. Engineers and industrial planners prioritize solutions that minimize environmental impact without compromising on performance. Lightweight gantry cranes fit this narrative perfectly, often utilizing recyclable materials and supporting innovative power solutions such as rechargeable battery-driven hoists, thereby reducing their carbon footprint. In conclusion, for any industry professional keen on optimizing their material handling processes, lightweight gantry cranes represent a strategic investment. They combine expert engineering with practical functionality, ensuring that businesses remain at the forefront of operational efficiency. By prioritizing attributes such as portability, reliability, and sustainability, these cranes not only meet but exceed the intricate demands of today's dynamic industrial landscape. Experts continuously advocate for their adoption, reflecting a seamless integration of trusted technology and strategic innovation tailored for future-ready operations.

Latest news

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025