Design and Implementation of Efficient Gantry Crane Bridge Systems for Industrial Applications

The Evolution and Impact of Gantry Crane Bridges

Gantry crane bridges have become an indispensable part of modern industrial spaces and construction sites. These specialized cranes are characterized by their unique overhead structure, which consists of a bridge spanning two or more supports, often with a hoist mechanism that allows for vertical lifting and lowering of materials. The evolution of gantry cranes has significantly impacted various sectors, including construction, shipping, and manufacturing, facilitating greater efficiency and safety.

Historically, the need for efficient material handling led to the development of cranes as early as ancient Greece. The design of crane bridges has evolved over centuries, but the concept of a gantry crane emerged prominently in the early 20th century as industries began to scale operations. The adaptability and robust capabilities of gantry cranes made them ideal for heavy lifting tasks. Unlike traditional cranes that require a large radius of operation, gantry cranes offer a compact design that allows for precise movements in confined spaces. This has proven particularly beneficial in warehouses, shipyards, and assembly plants, where space optimization is crucial.

One of the many advantages of gantry crane bridges is their versatility. They can be constructed from various materials, including steel and aluminum, and can be tailored to accommodate specific tasks. For instance, a lightweight aluminum gantry crane might be used for smaller operations, while a heavy-duty steel structure can handle weights exceeding several tons. This adaptability has further driven the use of gantry cranes across different industries, allowing them to be employed in various capacities—from loading and unloading containers at ports to assembling large industrial components.

gantry crane bridge

In addition to their versatility, gantry cranes enhance safety in the workplace. The design allows for a lower center of gravity compared to traditional cranes, which reduces the risk of tipping. Furthermore, many modern gantry crane systems come equipped with advanced safety features such as limit switches, emergency stops, and automated controls. These innovations not only protect workers but also minimize the potential for accidents, ultimately leading to increased productivity.

The integration of technology into gantry crane systems has revolutionized material handling. With the rise of automation in industries, gantry cranes can now be fitted with intelligent control systems that enable remote operation and real-time monitoring. This technological advancement allows for the collection of data regarding lifting operations, leading to better decision-making and operational optimization. As industries continue to embrace the Internet of Things (IoT), the potential for smart gantry crane systems will only expand, paving the way for more efficient and interconnected workplaces.

The impact of gantry crane bridges extends beyond material handling efficiency; they also contribute to the sustainability of operations. By reducing the need for additional equipment and minimizing manual handling, companies can decrease their overall carbon footprint. Many businesses are now focusing on energy-efficient designs, enabling them to operate within environmentally friendly guidelines while maintaining high productivity levels.

In conclusion, gantry crane bridges have transformed the way industries approach material handling and construction. Their evolution reflects a continuous pursuit of efficiency, safety, and adaptability in an ever-changing industrial landscape. As technology advances and the need for sustainable practices grows, gantry cranes will undoubtedly continue to play a pivotal role in shaping the future of construction and manufacturing. Their versatility, safety features, and integration of modern technology position them as a cornerstone of innovative industrial solutions.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

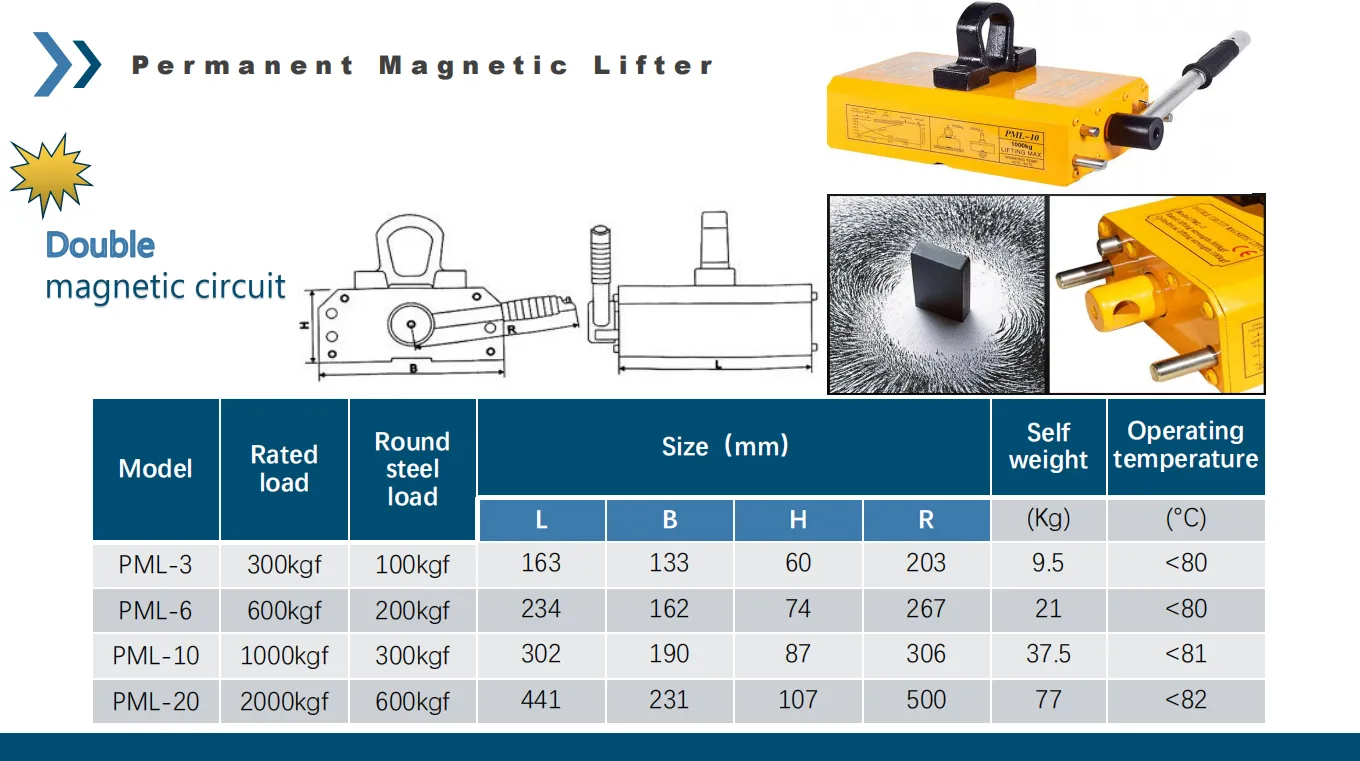

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025