Understanding the Benefits of Double Girder Overhead Cranes in Industrial Applications

Understanding Double Girder Overhead Cranes A Comprehensive Overview

In the realm of industrial lifting equipment, the double girder overhead crane stands out as a key player due to its robust design and versatility. These cranes are commonly employed in warehouses, manufacturing plants, and construction sites, where they facilitate the movement of heavy loads with efficiency and precision. This article delves into the features, advantages, and applications of double girder overhead cranes, providing insights into their significance in modern industrial settings.

Design Features

The double girder overhead crane consists of two main girders that run parallel to each other, supported by a bridge that spans the width of the workspace. This design allows for a more substantial lifting capacity compared to single girder cranes, enabling them to handle heavier loads with ease. Key components of the crane include

1. Main Girders The two horizontal girders that provide strength and support for the crane's structure. They allow for high lifting capabilities and stability. 2. End Trucks These are the assemblies that allow the crane to move along the runway beams. Each end truck is mounted on one of the main girders, facilitating smooth movement.

3. Cross Travel Mechanism This component enables the crane to move side-to-side across the workspace, enhancing its operational versatility.

4. Hoist The hoisting mechanism is responsible for lifting and lowering loads. It can be electric or manual, with electric hoists being the most common due to their efficiency and ease of use.

5. Control System Modern double girder overhead cranes are equipped with sophisticated control systems, allowing operators to maneuver the crane with precision. Remote controls and pendant controls are frequently used for ease of operation.

Advantages of Double Girder Overhead Cranes

The double girder overhead crane offers several advantages that make it a preferred choice for many industries

double girder overhead crane

1. Higher Load Capacities One of the primary benefits of the double girder design is its ability to lift heavier loads, often exceeding 100 tons. This makes it suitable for applications where substantial weight is a factor.

2. Greater Span The design permits wider spans between support beams, allowing for more operational space and flexibility in load positioning.

3. Improved Stability and Safety The two-girder setup enhances the stability of the crane, reducing the risk of tipping or swaying during operation. This provides a safer working environment for operators and nearby personnel.

4. Increased Hook Height The configuration of double girders allows for a higher hook height compared to single girders, maximizing lifting capability and enabling the handling of taller loads.

5. Customization Options Many manufacturers offer customizable options, allowing businesses to tailor cranes according to their specific operational needs.

Applications

Double girder overhead cranes are versatile and find applications in various industries

- Manufacturing Used for assembly lines, product handling, and machine maintenance. - Construction Ideal for lifting heavy construction materials on-site. - Warehousing and Distribution Efficient for loading and unloading heavy items, streamlining logistics. - Steel Mills and Power Plants Designed to handle extremely heavy and bulky loads with high precision.

Conclusion

In summary, double girder overhead cranes are essential machines in the industrial sector, recognized for their robust design and impressive lifting capabilities. Their flexibility, safety features, and advanced technology make them ideal for a wide range of applications. As industries continue to evolve, the demand for efficient and reliable lifting solutions such as the double girder overhead crane is expected to grow, supporting the ever-increasing need for productivity in heavy-duty operations. It is crucial for industries to invest in such equipment to ensure safety and efficiency in their material handling needs. As the world of industry progresses, these cranes will undoubtedly remain at the forefront of heavy lifting technology.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

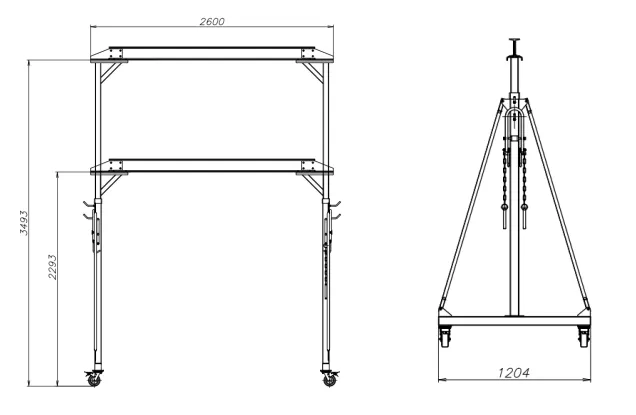

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025