Efficient Handling and Lifting Solutions for Sheet Metal Using Magnetic Technology

The Essentials of Sheet Metal Magnetic Lifters

In the world of manufacturing and construction, efficiency, safety, and precision are of paramount importance. One of the ingenious inventions developed to address these needs is the sheet metal magnetic lifter. This powerful tool has transformed how heavy sheets of metal are handled, offering a reliable solution for lifting, moving, and positioning metal components in various industrial applications.

What is a Sheet Metal Magnetic Lifter?

A sheet metal magnetic lifter is a device that uses the power of magnets to lift and hold heavy metal objects. It typically consists of a strong permanent magnet or an electromagnet, along with a control mechanism that allows operators to easily activate or deactivate the magnetic field. These lifters are designed specifically for flat, ferromagnetic materials such as steel and iron, making them ideal for handling sheet metal in manufacturing environments.

Benefits of Using Magnetic Lifters

1. Efficiency in Operations Traditional methods of lifting and moving heavy metal sheets often involve cranes, hooks, and manual labor, which can be time-consuming and labor-intensive. Magnetic lifters streamline this process, allowing operators to quickly and safely lift and transport sheets with minimal effort. This efficiency translates into improved productivity on the shop floor.

2. Enhanced Safety Safety is a cornerstone of industrial operations. Magnetic lifters significantly reduce the risk of accidents associated with lifting heavy loads. With the ability to securely grip metal sheets, they minimize the chances of slippage or dropping materials during transport. Operators can also maintain a safe distance from hazardous loads, decreasing the likelihood of workplace injuries.

3. Versatility Magnetic lifters can be used in a variety of applications, from manufacturing to construction and metalworking. They are capable of handling sheet metal of various sizes and thicknesses, making them a versatile tool for different tasks. Whether lifting sheets for assembly, positioning them for welding, or moving them in storage, magnetic lifters can adapt to a wide range of industrial needs.

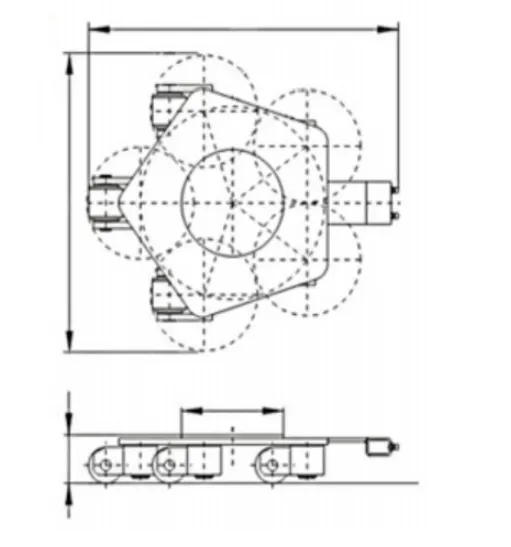

sheet metal magnetic lifter

4. Cost-Effectiveness While the initial investment in a high-quality magnetic lifter may be significant, the long-term savings are undeniable. By minimizing the need for additional lifting equipment, reducing labor costs, and increasing operational efficiency, businesses can realize substantial returns on their investment.

Types of Magnetic Lifters

There are generally two main types of magnetic lifters permanent magnetic lifters and electromagnetic lifters.

- Permanent Magnetic Lifters These devices utilize strong permanent magnets to create a constant magnetic field. They are typically lighter, more compact, and don't require a power source, making them suitable for many lifting applications. They are known for their reliability and ease of use.

- Electromagnetic Lifters These lifters generate a magnetic field using electricity. They offer adjustable lifting power, allowing for more control over the weight they can handle. However, they require a power source, which may limit their use in some situations.

Conclusion

The sheet metal magnetic lifter has established itself as an indispensable tool within various industries, facilitating safer and more efficient handling of heavy metal sheets. As manufacturing practices evolve and the demand for efficiency increases, magnetic lifters will continue to play a critical role in maximizing productivity and ensuring safety in metalworking environments. Investing in such technology not only benefits operational efficiency but also fosters a workplace culture where safety and innovation are prioritized.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025