Efficient Solutions for Warehouse Gantry Crane Operations and Management Strategies

Warehouse Gantry Crane An Essential Piece of Material Handling Equipment

In the contemporary industrial landscape, the efficiency of material handling operations plays a pivotal role in ensuring smooth workflows and maximizing productivity. Among the myriad of equipment designed for such tasks, the warehouse gantry crane stands out as an indispensable asset for numerous businesses. This crane type is especially valuable in warehouses due to its design, versatility, and efficiency in lifting and moving heavy loads.

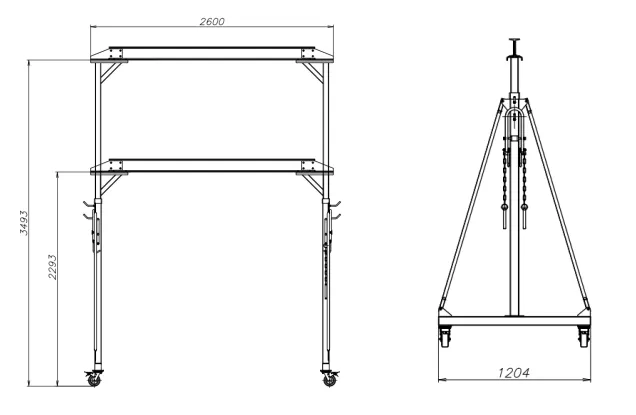

A warehouse gantry crane typically consists of a bridge that is supported by two upright legs, which are mounted on wheels. This structure allows the crane to move along a rail system, enabling it to cover wide areas within a warehouse or manufacturing facility. The design of gantry cranes allows for both indoor and outdoor use, making them versatile tools in various environments.

One of the key features of a warehouse gantry crane is its lifting capacity

. These cranes can handle loads ranging from a few hundred pounds to several tons, depending on the specifications of the equipment. This capability makes gantry cranes ideal for tasks such as transporting large pallets, lifting heavy machinery, or moving bulk materials. The ability to lift substantial weights while maintaining stability is crucial for ensuring worker safety as well as the protection of valuable equipment and materials.warehouse gantry crane

The operational efficiency of a warehouse gantry crane is another benefit that cannot be understated. With the integration of electric hoists and remote control systems, operators can manage material movement with precision and ease. This enhances productivity as it significantly reduces the time and labor required to move heavy items around the warehouse. Moreover, many modern gantry cranes are equipped with advanced features such as programmable logic controllers (PLCs) and variable frequency drives (VFDs), which further optimize their performance by allowing for smoother operation and better load handling.

Warehouse gantry cranes are also customizable, which means they can be tailored to meet the specific needs of a business. Various sizes, configurations, and lifting mechanisms can be designed to accommodate unique operational requirements. Additionally, they can be constructed from different materials, including steel and aluminum, ensuring that they are durable enough to withstand the rigors of daily use.

Safety is paramount in any workplace, and warehouse gantry cranes are designed with several safety features to minimize the risk of accidents. These cranes often come with emergency stop buttons, overload protection systems, and anti-sway mechanisms to ensure safe operation. Training operators in the proper use of gantry cranes is essential, as it helps develop a safety culture within the organization. Regular maintenance and inspections should also be conducted to ensure the equipment remains in optimal working condition.

In conclusion, the warehouse gantry crane is a vital component of modern material handling systems. Its ability to lift and transport heavy loads with efficiency and safety makes it a preferred choice for a variety of industries, from manufacturing to construction. As businesses continue to prioritize productivity and safety in their operations, investing in a warehouse gantry crane can yield significant returns in terms of improved workflow efficiency and operational effectiveness. Whether for lifting heavy equipment or moving large quantities of materials, gantry cranes remain an essential tool that enhances the overall functionality of a warehouse environment.

-

the-power-of-trolley-cargo-and-machinery-moving-solutionsNewsAug.22,2025

-

exploring-magnetic-lifting-devices-for-efficient-steel-plate-handlingNewsAug.22,2025

-

the-essential-guide-toportal-craneNewsAug.22,2025

-

enhancing-efficiency-in-permanent-magnetic-liftersNewsAug.22,2025

-

heavy-duty-machinery-movers-and-material-handling-solutionsNewsAug.22,2025

-

the-comprehensive-guide-to-adjustable-gantry-cranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025