Efficient Strategies for Streamlining Heavy Equipment Relocation and Handling in Industrial Settings

The Role and Importance of Machinery Movers in Industry

In today's fast-paced industrial environment, the movement and relocation of heavy machinery are crucial for various sectors, from manufacturing to construction. Machinery movers play an essential role in this process, ensuring that equipment is safely and efficiently transported, installed, or reconfigured. This article delves into the significance of machinery movers, their techniques, and the safety measures they employ.

Machinery movers are specialized professionals equipped with the skills and tools necessary to handle large, heavy, and often delicate equipment. These experts are not only trained in the physical aspects of machinery relocation but also in understanding the implications of moving such devices. Whether it's a CNC machine, a press, or a large industrial crane, each piece of equipment requires specific handling to prevent damage and ensure operational integrity.

One of the critical aspects of machinery moving is the planning phase. Professionals begin by assessing the machinery to be moved and the environment in which the move will take place. This involves measuring dimensions, understanding weight distribution, and identifying any potential obstacles. A detailed plan must be formulated that outlines the steps for safely lifting, transporting, and setting up the equipment in its new location. This meticulous planning is essential not only for the success of the operation but also for ensuring the safety of the workers involved.

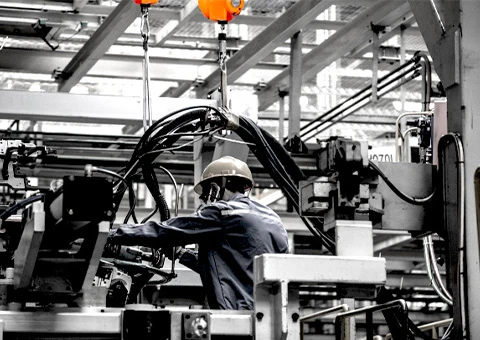

machinery mover

The tools and techniques employed by machinery movers are varied and often require significant investment in specialized equipment. Machinery movers typically use hydraulic lifts, cranes, dollies, and skates to facilitate the movement of heavy equipment. Hydraulic systems are particularly beneficial as they offer the capacity to lift and maneuver very heavy loads with minimal effort, thereby reducing the risk of injury. In addition to these tools, movers often use winches and rigging supplies to secure the machinery during transportation, further enhancing safety.

Safety is a paramount consideration in the moving of heavy machinery. Machinery movers adhere to strict safety protocols to minimize the risk of accidents. This includes the use of personal protective equipment (PPE) such as hard hats, gloves, and steel-toed boots. Additionally, movers are trained to recognize potential hazards in their working environment, such as uneven flooring or overhead obstructions. The employment of safe lifting techniques and proper weight distribution is critical in preventing injuries and ensuring that the equipment remains intact during the move.

Moreover, machinery movers often collaborate with other professionals, such as engineers and contractors, to ensure a seamless operation. This teamwork is essential, especially when dealing with large installations that may require modifications to existing structures or infrastructure. Effective communication between all parties helps mitigate risks and streamline the machinery relocation process.

In conclusion, machinery movers are an indispensable part of the industrial landscape. Their expertise not only ensures the safe transport and installation of heavy equipment but also contributes to the overall efficiency of industrial operations. By combining careful planning, specialized tools, and a strong emphasis on safety, machinery movers play a vital role in keeping industries moving forward. As technology continues to advance and industries evolve, the skills and techniques of machinery movers will remain essential in facilitating the growth and development of various sectors.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025