Efficient Techniques for Rigging and Moving Heavy Machinery in Industrial Settings

Rigging and Machinery Movers Ensuring Safe and Efficient Transport

In various industries, the movement and installation of heavy machinery and equipment are vital tasks that require precision, skill, and specialized knowledge. Rigging and machinery movers play a crucial role in this process, ensuring that heavy items are transported safely and efficiently from one location to another. This article explores the essential aspects of rigging and machinery moving, highlighting the techniques, equipment, and safety measures involved.

Understanding Rigging

Rigging refers to the process of using ropes, chains, pulleys, and other equipment to lift, lower, and move heavy objects. This procedure is common in construction, manufacturing, and entertainment industries, among others. Proper rigging ensures that machinery can be securely hoisted and transported, minimizing the risk of accidents or damage during the process.

A variety of rigging techniques exist, depending on the type of machinery and the environment in which it is being moved. Some common rigging methods include the use of slings, which are straps that provide support; hoists that lift the load; and dollies or rollers that facilitate movement on flat surfaces. Each piece of equipment must be chosen carefully and inspected regularly to ensure it meets safety standards and can handle the weight and dimensions of the load.

The Role of Machinery Movers

Machinery movers specialize in the physical transportation of heavy equipment. They are trained professionals who understand the complexities of moving large machines, including industrial equipment, generators, boilers, and more. Their expertise is crucial in ensuring that machinery is moved without incident and can be reinstalled correctly and efficiently at the destination.

rigging and machinery movers

Machinery movers utilize various tools and equipment, such as forklifts, cranes, and specialized vehicles designed to transport heavy loads. These professionals often work alongside riggers to ensure that the lifting and moving processes are coordinated. By collaborating, they create a seamless operation that prioritizes safety and effectiveness.

Safety Considerations

Safety is paramount in rigging and machinery moving. Both riggers and machinery movers must adhere to strict safety regulations to protect themselves, their team, and the equipment being handled. Before commencing any operation, a thorough risk assessment is conducted to identify potential hazards and establish safety measures.

Workers are trained to use personal protective equipment (PPE), such as helmets, gloves, and steel-toed boots, to minimize injury risks. Moreover, regular safety drills and training sessions are important to ensure that all team members are familiar with the proper procedures and protocols.

Communication is another vital aspect of safety in rigging and machinery moving operations. Clear communication among team members helps to coordinate movements, making it easier to manage tasks efficiently and reduce the risk of miscommunication that could lead to accidents.

Conclusion

Rigging and machinery moving are essential operations in various industries that demand skilled professionals and specialized equipment. By combining technical knowledge, practical skills, and a commitment to safety, riggers and machinery movers ensure that heavy equipment is transported and installed securely and efficiently. As industries continue to evolve and machinery grows larger and more complex, the importance of these professionals will only increase, underscoring their crucial role in maintaining operational efficiency and safety in the workplace.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

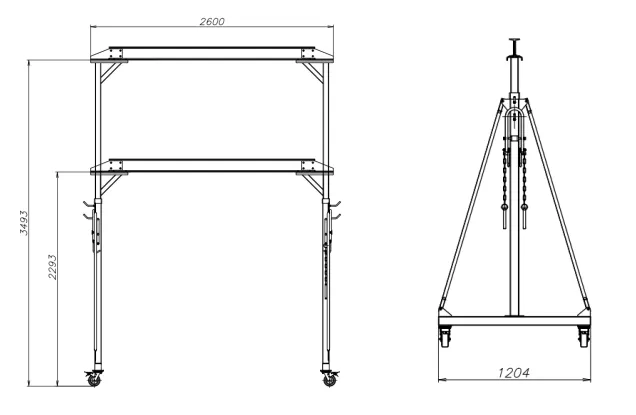

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025