Efficient Solutions for Heavy Equipment Transportation and Relocation Services

The Essential Role of Equipment Movers in Modern Industries

In today's fast-paced industrial landscape, the movement of heavy machinery and equipment is a critical operation that requires specialized skills, tools, and expertise. Equipment movers play an essential role in various sectors, including manufacturing, construction, and logistics, ensuring that heavy and often cumbersome tools and machines are transported safely and efficiently. This article explores the importance of equipment movers, the challenges they face, and the technologies that are transforming their work.

The Importance of Equipment Movers

Equipment movers are professionals trained to relocate heavy machinery and equipment from one place to another. Whether it’s transferring industrial machines within a factory, relocating construction equipment to a job site, or transporting goods across state lines, these experts ensure that all operations run smoothly without compromising safety.

One of the primary reasons for hiring equipment movers is safety. Heavy equipment can be dangerous not only to the operators but also to those working nearby. Equipment movers are trained to handle these machines with care, using specialized techniques and tools to mitigate risks. They understand the weight distribution and balance of heavy equipment, allowing them to maneuver these items without causing damage or injury.

Additionally, equipment movers contribute significantly to operational efficiency. In industries where every minute counts, having professionals who can quickly and effectively move equipment minimizes downtime. This efficiency can lead to cost savings and increased productivity, which are vital in maintaining competitive edges in respective markets.

Challenges Faced by Equipment Movers

Despite their importance, equipment movers face numerous challenges in their line of work. One major obstacle is the sheer weight and size of the machinery they work with. Moving large equipment often requires meticulous planning and execution to prevent accidents and ensure that the items are transported securely.

equipment movers

Further complicating these operations is the need for adherence to regulations and safety standards. Depending on the jurisdiction, equipment movers must navigate various legal requirements regarding transportation, including obtaining permits, following specific routes, and meeting safety guidelines. Failing to comply can result in fines and hinder project timelines.

Weather conditions also pose a significant challenge, especially for outdoor operations. Rain, snow, or extreme heat can impede the movement of machinery, increase risks of accidents, and delay schedules. Equipment movers must remain adaptable and ready to adjust their plans according to weather forecasts while still prioritizing safety and efficiency.

Technological Advancements in Equipment Moving

As industries evolve, so too do the tools and methods used by equipment movers. Innovative technologies are enhancing the efficiency and safety of moving machinery. For instance, the use of automated guided vehicles (AGVs) is becoming increasingly popular in warehouses and manufacturing plants. These machines can navigate themselves, carrying loads without the need for human intervention, reducing the risk of accidents.

Additionally, advancements in rigging techniques, such as the use of electronic monitoring systems, allow for better tracking of weight distribution and stress points during transportation. This technology aids equipment movers in making informed decisions while moving heavy items, ensuring a higher level of safety.

Moreover, virtual reality (VR) training programs are emerging to prepare equipment movers for real-world scenarios. These training systems help workers practice their skills in a controlled environment, allowing them to learn how to handle various types of equipment without the dangers associated with actual machinery.

Conclusion

Equipment movers are an indispensable part of modern industries, ensuring the safe and efficient movement of heavy machinery. Their expertise helps businesses maintain productivity while adhering to safety regulations. Despite the challenges they face, continuous technological advancements are paving the way for safer and more efficient practices in the field. As industries grow and evolve, the role of equipment movers will remain vital, underpinning the operational success of various sectors.

-

Portable 2000 lb Gantry Crane | Heavy-Duty & AdjustableNewsAug.30,2025

-

Versatile Lifting Solutions with Gantry and Overhead CranesNewsAug.29,2025

-

The Versatile Mobile Gantry Crane SolutionNewsAug.29,2025

-

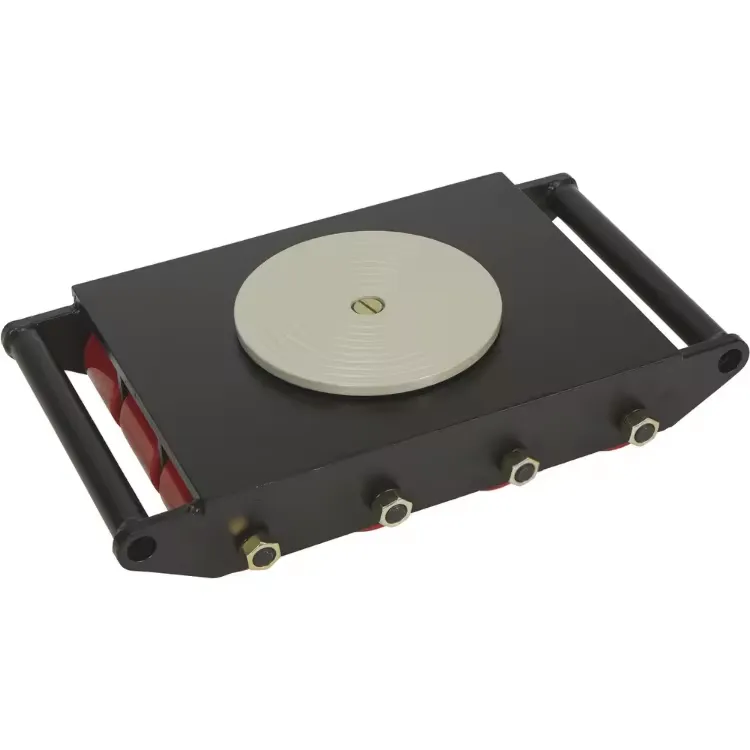

Reliable Movement with Heavy Machinery Skates and RollersNewsAug.29,2025

-

Reliable Lifting Performance with 2000 lb Gantry Crane and 2 Ton Overhead SystemsNewsAug.29,2025

-

Maximize Lifting Efficiency with PML Magnetic LiftersNewsAug.29,2025

-

Efficient Relocation Starts with Reliable Machinery MoversNewsAug.29,2025