Essential Equipment for Safely Handling Heavy Loads and Optimizing Moving Operations

Heavy Load Moving Equipment Ensuring Safety and Efficiency

Moving heavy loads is a common necessity in various industries, including construction, manufacturing, and logistics. The safe and efficient movement of such loads is crucial, not only for productivity but also for the safety of the workers involved. Doing this manually is often impractical, which is where heavy load moving equipment comes into play. This article will explore the different types of equipment available, their benefits, and important safety considerations.

Types of Heavy Load Moving Equipment

There is a wide range of equipment designed to handle heavy loads. Some of the most commonly used include

1. Forklifts These versatile machines are essential in warehouses and construction sites. They come in various sizes and types, including counterbalance, reach trucks, and pallet jacks, making them suitable for moving heavy pallets, materials, and even machinery.

2. Cranes For extremely heavy loads that cannot be moved with forklifts or other equipment, cranes are indispensable. They can lift and move loads vertically and horizontally, making them essential in construction, shipping, and heavy manufacturing.

3. Dollies and Hand Trucks While typically used for lighter loads, heavy-duty dollies and hand trucks can effectively handle substantial weights when properly used. They provide a manual option for moving heavy items over short distances.

4. Rigging Equipment This includes slings, shackles, and hoists, which are crucial in securing and lifting heavy loads. Rigging techniques ensure that loads are balanced and safely moved, especially when using cranes.

5. Pallet Jacks These are specifically designed for lifting and moving pallets. They can handle significant weights and are a staple in warehouse operations for transporting goods over short distances.

Benefits of Using Heavy Load Moving Equipment

heavy load moving equipment

The advantages of using heavy load moving equipment are numerous

- Increased Safety One of the paramount benefits is the safety it provides. Heavy loads can pose serious risks when moved manually. Equipment like forklifts and cranes minimize the chances of injury by allowing machines to handle the weight.

- Improved Efficiency Heavy equipment can move loads much faster than manual labor. This speed translates to higher productivity, enabling businesses to meet deadlines and fulfill orders more efficiently.

- Cost-Effective Although the initial investment in heavy moving equipment may be significant, it can lead to long-term savings. Reduced labor costs, minimized downtime due to injuries, and enhanced operational speed contribute to overall cost efficiency.

- Versatility Many heavy load moving tools can handle various types of materials, from pallets of boxes to large machinery. This versatility allows businesses to invest in fewer types of equipment while still meeting diverse moving needs.

Safety Considerations

While heavy load moving equipment greatly enhances safety, it is crucial to follow best practices to mitigate risks further. Operators should receive proper training to understand the equipment’s mechanisms and safety protocols. Regular maintenance and inspections are necessary to ensure equipment is in good working condition before use.

Additionally, implementing safety protocols such as clear signage, designated pathways for moving equipment, and proper load balancing techniques can significantly reduce the likelihood of accidents. Using adequate personal protective equipment (PPE) such as gloves and helmets is also crucial.

Conclusion

Heavy load moving equipment plays an essential role in various industries, offering solutions that ensure safety, efficiency, and versatility. Businesses that prioritize the proper use and maintenance of this equipment not only protect their workers but also enhance their operational capabilities. As industries continue evolving, the advancement in heavy load moving technology will likely lead to even safer and more efficient moving solutions.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

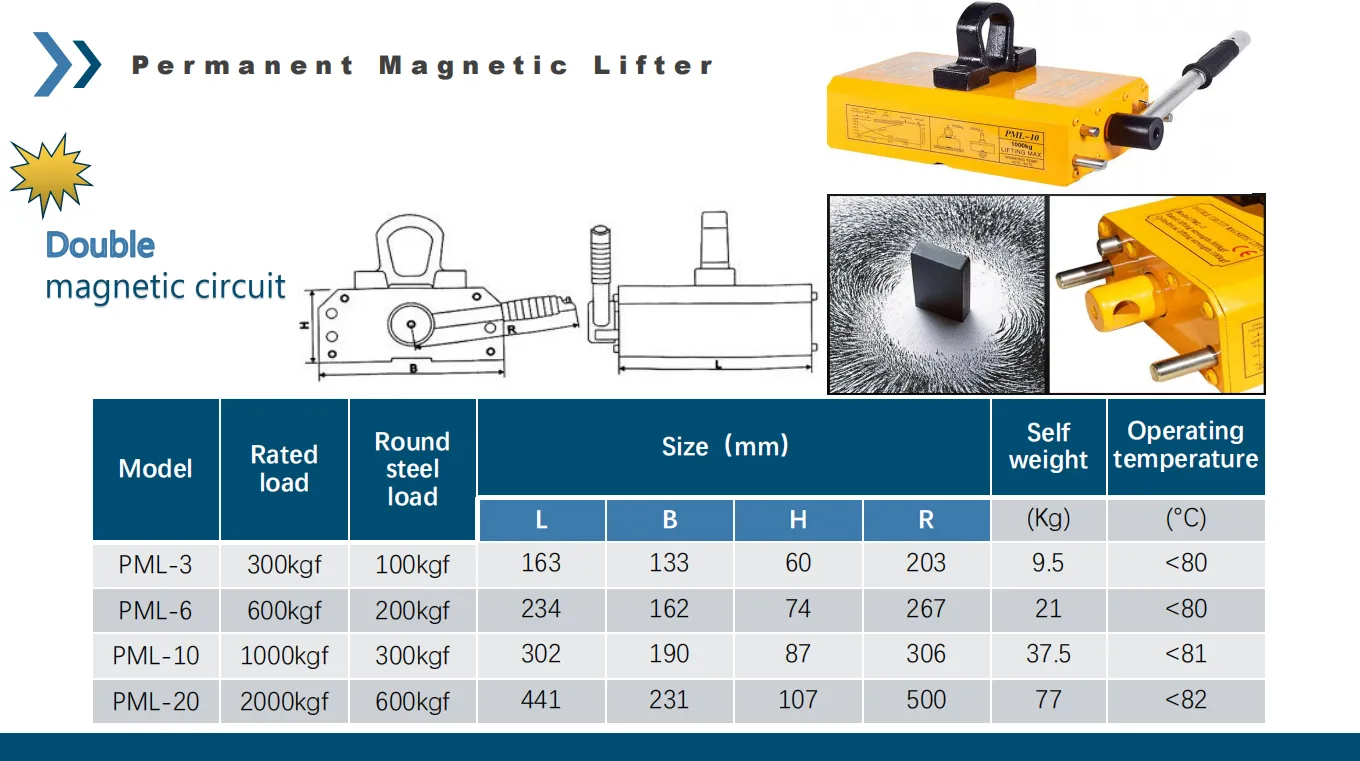

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025