Exploring the Benefits and Applications of Floor Mounted Gantry Cranes in Industrial Settings

Understanding Floor Mounted Gantry Cranes A Comprehensive Overview

In the world of material handling and industrial operations, efficiency and safety are paramount. One of the vital tools employed to achieve these goals is the floor mounted gantry crane. This versatile equipment is widely used in factories, warehouses, and construction sites for its ability to lift heavy loads with precision and ease. In this article, we will explore the features, benefits, and applications of floor mounted gantry cranes.

What is a Floor Mounted Gantry Crane?

A floor mounted gantry crane is a type of overhead crane that consists of a rectangular frame supported by vertical columns, which rests on the ground. This structure allows the crane to move across a designated path, typically aided by wheels or rails. Unlike traditional overhead cranes that are suspended from the ceiling, gantry cranes offer the advantage of being easily positioned wherever needed on the shop floor. They can also be designed for adjustable heights, catering to a wide range of applications.

Key Features

2. Mobility Many gantry cranes are equipped with wheels or castors, allowing them to be moved easily across different areas. This mobility is particularly valuable in settings where tasks are dynamic and require equipment to be repositioned frequently.

3. Height Adjustment Some models feature adjustable legs, which let users customize the height of the crane to suit various lifting needs, accommodating different load sizes and application requirements.

4. Ease of Operation Most floor mounted gantry cranes are designed with user-friendly controls, allowing operators to lift, lower, and move loads safely and efficiently.

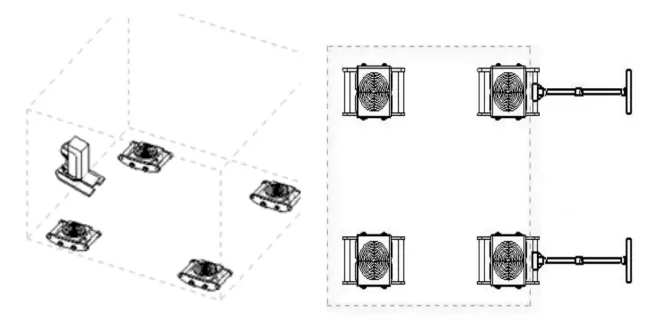

floor mounted gantry crane

Benefits

1. Safety The design of gantry cranes significantly enhances workplace safety. They are built with features such as limit switches and emergency stop buttons, minimizing the risk of accidents during operation.

2. Cost-Effectiveness Compared to permanent overhead lifting systems, floor mounted gantry cranes can be a more affordable solution for businesses. They require minimal installation and can be relocated as needed, providing versatility without the high costs of structural modifications.

3. Enhanced Productivity By facilitating the movement of heavy materials and components, gantry cranes help streamline workflows. This efficiency can lead to increased productivity as tasks can be completed more quickly and with less manual handling.

4. Customizability Manufacturers often offer floor mounted gantry cranes in various configurations to meet specific industry needs, allowing businesses to select models that best fit their operational requirements.

Applications

Floor mounted gantry cranes find applications across various industries, including manufacturing, construction, shipping, and automotive. In manufacturing, they are commonly used to lift and position heavy machinery, while in construction, they facilitate the movement of building materials. Additionally, in shipping and logistics, these cranes aid in loading and unloading goods, enhancing overall efficiency.

Conclusion

In conclusion, floor mounted gantry cranes are a vital tool in modern industrial settings, offering a unique blend of strength, mobility, and safety. Their versatility and cost-effectiveness make them ideal for a multitude of applications, allowing businesses to optimize their operations effectively. As industries continue to evolve, the role of gantry cranes remains significant, contributing to increased productivity and enhanced safety standards in material handling processes. Whether in a small workshop or a large manufacturing facility, the benefits of adopting a floor mounted gantry crane can be substantial, positioning companies for success in today’s competitive environment.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025