Exploring the Benefits and Applications of Overhead Gantry Cranes in Industrial Settings

Understanding Overhead Gantry Cranes A Vital Component in Modern Industry

Overhead gantry cranes are essential pieces of equipment widely used in various industrial settings, from manufacturing plants to shipping yards. These cranes are designed to lift and move heavy loads efficiently, which plays a crucial role in enhancing productivity and safety in workplaces that handle heavy materials.

Design and Structure

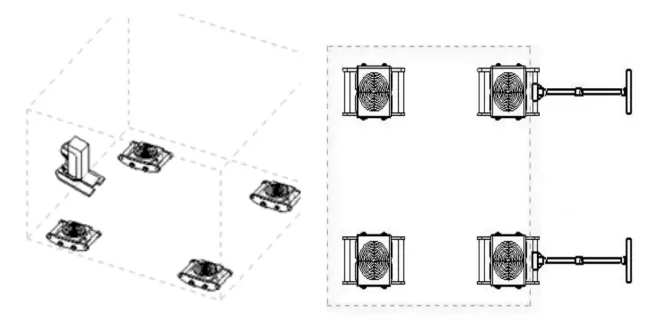

The basic structure of an overhead gantry crane consists of a bridge spanning two or more support beams. The overhead structure is mounted on a set of wheels or rails that allow it to move horizontally across a specified area. The crane features a hoisting mechanism located on the bridge, which can lift and lower loads. This design enables the crane to cover a large workspace, maximizing efficiency by allowing workers to move materials quickly between different points.

Types of Overhead Gantry Cranes

Overhead gantry cranes come in various configurations to meet specific needs. The most common types include single girder cranes, which are lighter and best for low-capacity lifting, and double girder cranes, which provide higher strength and can handle heavier loads. Additionally, some cranes are designed for outdoor use, featuring robust weather-resistant components, while others are optimized for indoor environments.

Key Advantages

The advantages of employing overhead gantry cranes are manifold. They occupy minimal floor space, allowing more room for other operations, which is particularly beneficial in confined or busy environments. Their ability to handle large and heavy loads reduces the need for manual lifting, decreasing workplace injuries and improving safety standards. Furthermore, these cranes can be equipped with various hoisting mechanisms and attachments, making them versatile tools for diverse tasks.

over head gantry crane

Applications in Different Industries

Overhead gantry cranes are utilized across various sectors. In construction, they are pivotal for lifting steel beams and large prefabricated components. The manufacturing industry relies on these cranes for the assembly line processes, moving components from one station to another with ease. In logistics, they help in loading and unloading containers and heavy goods from trucks and ships, significantly speeding up the shipping process. Additionally, they are used in the aerospace and automotive industries for assembling complex machinery and vehicles.

Safety Considerations

While overhead gantry cranes considerably enhance operational efficiency, safety must always be a priority. Operators must undergo thorough training to understand crane controls and safety protocols. Regular maintenance of the crane is crucial to prevent malfunctions, which could lead to accidents. Implementing safety measures such as load limiters, emergency stop buttons, and warning systems further ensures a safe working environment.

Future Trends

Looking ahead, the evolution of overhead gantry cranes will undoubtedly continue. Advancements in automation and smart technology are paving the way for cranes that can operate with minimal human intervention. Features such as remote control operation, integrated sensors for load monitoring, and automated movement paths are becoming more prevalent. This shift not only optimizes efficiency but also enhances safety by reducing the risks associated with manual operation.

Conclusion

In summary, overhead gantry cranes are indispensable tools in modern industry, bringing significant advantages in terms of efficiency, safety, and versatility. As industries continue to evolve with technological advancements, the importance and functionality of these cranes will only increase, solidifying their role as a cornerstone in material handling operations across various sectors. Investing in quality cranes and ensuring their safe operation will ultimately contribute to the success and safety of industrial operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025